It is a sectional and semi-finished steel product obtained from the ingot rolling process or continuous casting process. The cross section of slabs is rectangular, not square, unlike ingots and ingots, and is used as a raw material for making flat rolling products such as coils and hot rolled sheets. For more information on the steel slabs market visit our site.

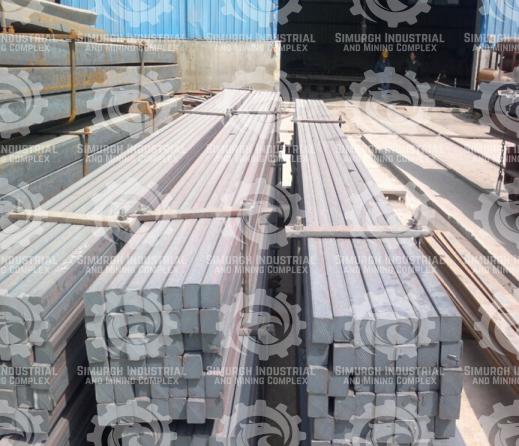

What are steel slabs?

Slab is a rectangular semi-finished steel product that becomes the final product (steel sheets) after one or more processing steps in rolling mills and sheet manufacturers. This product is known as Takhtal in Iran, pronounced in English (plate). The price of slab as a semi-finished steel product in the production of steel sheet and application sheet is very important due to the quality production of this product in Iran. Most plates are made of carbon steel, but stainless steel plates are also available. This product consists of alloys such as iron, chromium, copper, manganese, nickel, silicon, nickel and molybdenum.

Slab is a rectangular semi-finished steel product that becomes the final product (steel sheets) after one or more processing steps in rolling mills and sheet manufacturers. This product is known as Takhtal in Iran, pronounced in English (plate). The price of slab as a semi-finished steel product in the production of steel sheet and application sheet is very important due to the quality production of this product in Iran. Most plates are made of carbon steel, but stainless steel plates are also available. This product consists of alloys such as iron, chromium, copper, manganese, nickel, silicon, nickel and molybdenum.

Its specifications are determined by standard codes, usually engraved on the end of the sheet. Standard dimensions of steel plates As a rectangular steel product, the plates have a width of 650 mm to a maximum of 2000 mm, a thickness of 200 to 250 mm and a variable length of 4 to 12 meters. The production size of this product depends on the application. The highest production rate of this product is 230 mm thick, 1250 mm wide (one meter and 25 cm) 12 meters long. Slabs have a limited market and around twenty million tons of slabs are produced annually in the world and put into the sales cycle.

Flooring applications Billet, Bloom and Slabs are the brands of 22 steel products used in the manufacture of various profile and steel products. Plates are used in the heavy machinery industry as well as to make a variety of flat steel products such as plates, plates and coils. Because the thickness of this sheet is very small due to the standard dimensions described, it may cause problems during cutting and high-specification machines should be used for cutting. The blast furnace method is a traditional method that uses indirect reduction to produce plates. Considering that Iran has high quality coal resources, this method is a practical method. First, iron ore containing lime and coke is brought to a blast furnace and crude iron (molten cast iron) is extracted.

To remove impurities from molten steel obtained from crude iron, crude steel is obtained by removing carbon and adding oxygen. Then, in the continuous casting unit, the melt is poured into the mold, the product is separated from the mold and the plate is cooled by spraying cold water and turned into a frozen ingot. Finally, desired plate lengths can be obtained with different cuts. For more information on steel slabs price visit our site.

Focal suppliers of steel slabs in 2021

Our collection is one of the Focal suppliers of steel slabs in 2021 and delivers this product to the customer at a reasonable price. Therefore, you can refer to our site for more information about steel slabs to export.

Our collection is one of the Focal suppliers of steel slabs in 2021 and delivers this product to the customer at a reasonable price. Therefore, you can refer to our site for more information about steel slabs to export.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@