Steel-concrete composite slab systems are known to be one of the most economical methods of building roofs for buildings. This system consists of composite sections of reinforced concrete slabs on trapezoidal sheets that are connected to steel beams and girders. For more information about steel slabs, visit our site.

Which steel is best for slab?

The most common type of rebar is carbon steel, which is typically made up of hot round bars with deformation patterns. Other types that are readily available include stainless steel and composite rods made from fiberglass, carbon fiber, or basalt fiber. Steel reinforcement bars can also be coated with an epoxy resin that is coated to withstand further corrosion effects in saline environments as well as ground-based structures. Concrete is a material that is very strong in terms of compression but relatively weak in terms of tension. To compensate for this imbalance in the behavior of concrete, reinforcing bars are poured in to absorb tensile loads. Most steel reinforcement is divided into primary and secondary reinforcement, but there are other minor uses as well:

The most common type of rebar is carbon steel, which is typically made up of hot round bars with deformation patterns. Other types that are readily available include stainless steel and composite rods made from fiberglass, carbon fiber, or basalt fiber. Steel reinforcement bars can also be coated with an epoxy resin that is coated to withstand further corrosion effects in saline environments as well as ground-based structures. Concrete is a material that is very strong in terms of compression but relatively weak in terms of tension. To compensate for this imbalance in the behavior of concrete, reinforcing bars are poured in to absorb tensile loads. Most steel reinforcement is divided into primary and secondary reinforcement, but there are other minor uses as well:

- 1. The primary reinforcement consists of steel which is used to ensure the necessary strength of the entire structure to support the design loads. Secondary reinforcement, also known as thermal reinforcement or distribution, provides local strength sufficient to limit crack and stress resistance due to effects such as temperature changes and shrinkage due to its durability and aesthetics.

- 2. Used to provide resistance to dense loads by providing local strength and sufficient stiffness to transfer loads over a larger area.

- 3. It can also be used to hold other steel bars in the correct position to place their loads on.

- 4. Metal outer bars can constrain and reinforce masonry structures, as shown in the Novyansk Tower or in ancient structures in Rome and the Vatican.

Steel has a coefficient of thermal expansion that is almost the same as that of modern concrete. If this is not the case, this leads to problems due to additional longitudinal and vertical stresses at temperatures other than the ambient temperature. Although the reinforcement has ribs with which it is mechanically attached to the concrete despite the high stresses, performance can be drawn from the concrete, which often leads to a major collapse. To avoid such damage, the rebar is either embedded deeply into adjacent structural members or bent and hooked at the end to lock it around the concrete and other rebar.

The first method increases the friction of the bar in place, while the second method uses a high compressive strength of concrete. Ordinary rebars are made of imperfect steel and cause rust. Typically, a concrete cover can keep a pH above 12 to avoid a corrosion reaction. Very little concrete coating can compromise this protection by carbonation from the surface and the ingress of salt. Excessive concrete cover can result in greater widths, which also protects the local guard. For more information on steel bars used in slabs please visit our website.

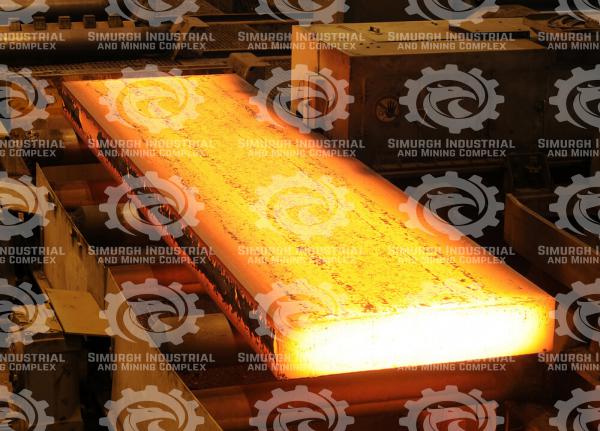

Domestic production of steel slabs

Domestic production of steel slabs is done by our company and we have produced this product with suitable raw materials and export it to other countries, so for more information about prime steel slabs, visit our site.

Domestic production of steel slabs is done by our company and we have produced this product with suitable raw materials and export it to other countries, so for more information about prime steel slabs, visit our site.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@