We are aware of the importance of steel products in our daily lives, which is how we learned about the different types of steel that are produced and the global market for this precious commodity. We came to learn about the various kinds of steel that are created since we are aware of the effects that steel commodities have on our daily lives.

Steel can be produced in a variety of forms, including tool steel, carbon steel, alloy steel, and stainless steel, among others. One of the most popular varieties of steel is a tool steel. Keep reading to learn more about the many types of steel that are mixed to create stainless steel.

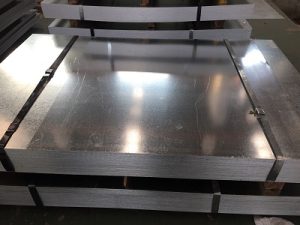

Stainless steel plate thickness chart in mm

All of the iron-based alloys collectively referred to as stainless steel are renowned for their ability to withstand heat and corrosion. Stainless steel has a very high corrosion resistance compared to other types of steel since it includes at least 10.5 percent chromium.

This is one of the main characteristics that set stainless steel apart from other types of steel. In a similar way to other varieties of steel, stainless steel is primarily composed of iron and carbon, with chromium serving as the most significant alloying element. Other common alloys present in stainless steel include nickel, magnesium, molybdenum, and nitrogen.

Stainless steel is widely employed in the production of a wide range of parts and components across a variety of different industries since it boasts so many desirable properties. Most notably, because it contains chromium, it has a remarkable level of corrosion resistance.

Steels having a minimum chromium content of 10.5 percent exhibit corrosion resistance that is almost 200 times greater than steels without chromium. The material’s high strength and durability, resistance to high and low temperatures, increased formability and ease of fabrication, low maintenance requirements, long-term durability, attractive appearance, environmental friendliness, and recyclable nature are additional features that draw customers.

Stainless steel doesn’t need to be treated further once it’s in use, and it also doesn’t need to be coated or painted. In addition to other factors, in order to fulfill the objective of increasing the steel project’s effectiveness while simultaneously keeping costs as low as is practically achievable.

Stainless steel is utilized in numerous applications, is easily sterilized, and is completely recyclable. In actuality, stainless steel products are used every day by regular people. Stainless steel is used everywhere, including in the kitchen, the car, the doctor’s office, and our homes.

Stainless steel thickness (mm)

Gauges are used to determine the depth of the material on a sheet of metal. These units are not a part of any accepted measurement system, including the metric system. They instead have no connection to the other measurement methods at all.

By keeping a gauge conversion chart in a handy place, it is simple to determine the exact thickness of a sheet of metal in inches or millimeters. For illustration purposes, a 14 gauge stainless steel has a thickness of.07812 inches. The gauge’s reading of 14 has absolutely no influence at all on the measures themselves.

The fact that the gauge thicknesses vary depending on the type of sheet metal being discussed is crucial information to be aware of. Consider the thickness of 12-gauge across the material types given below: stainless steel is 0.105 inches thick, aluminum is 0.080 inches thick, copper is 0.108 inches thick, and brass is 0.081 inches thick.

304 stainless steel sheet thickness

The austenitic kind of stainless steel is type 304 stainless steel, which is also known as 18/8 stainless steel on occasion. When compared to ferritic 430, it has a higher nickel content than that material has. Type 304 stainless steel is not magnetic, offers superior resistance to corrosion, and has a higher strength rating than Type 430.

Type 304 is unaffected by foods, disinfectants, the vast majority of organic chemicals and dyes, and a wide variety of inorganic compounds. Type 304 is also resistant to corrosion from a wide variety of inorganic compounds.

Sinks, tabletops, stovetops, refrigerators, and steam tables are all possible applications for 304 because of the material’s ability to withstand the corrosive effects of a variety of acids that can be present in foods such as meats, vegetables, milk, and fruits. It also makes use of a wide variety of other implements, such as cutlery, cookware, and various pieces of kitchen equipment.

Nitric acid and other organic acids are just two of the many corrosives that Type 430 has significant resistance to. Type 430 is also resistant to many other corrosives. When given a high polish or buffed to a high sheen, it achieves the highest level of corrosion resistance.

Comparable to Type 304 in terms of its resistance to pitting and crevice corrosion, this material has a high level of tensile strength. The resistance of Grade 430 to stress corrosion cracking is exceptionally high, similar to that of other ferritic grades.

Stainless steel sheet price

The word “stainless” steel actually refers to a wide range of steel kinds. Stainless steel is produced in a two-step process primarily from iron and carbon, like all other types of steel. The addition of chromium and other alloying elements like nickel to stainless steel results in a product that is resistant to corrosion.

Steel corrodes as a result of iron’s natural occurrence in combination with other elements. Iron ore is unstable and rapidly recombines with oxygen when it is artificially processed into a pure form to manufacture steel.

Chromium oxide, which is created when chromium is added to steel, serves as a protective surface to stop rust from occurring, as it would with regular steel. According to the usage or environment for which the steel is intended, chromium is added in amounts ranging from 10.5 to 30 percent. Although there are over 100 different stainless steel grades, they can be divided into five main types:

The most popular variety of stainless steel is austenitic. In addition to having outstanding mechanical qualities over a wide temperature range, it offers excellent corrosion and heat resistance. Household appliances, industrial pipelines and vessels, building materials, and facades of buildings all use austenitic steel.

Similar to mild steel (most popular steel), ferritic stainless steel has superior resistance to heat, corrosion, and cracking. Ferritic steel is frequently used in indoor architecture, boilers, and washing machines.

Martensitic stainless steel is extremely strong and hard, but it does not have the same level of corrosion resistance as austenitic or ferritic grades. It is used to create knives and turbine blades and includes about 13% chromium.

Due to the combination of austenitic and ferritic steels, duplex stainless steel is both durable and malleable. The paper, pulp, shipbuilding, and petrochemical industries all use duplex steels.

Precipitation-hardening stainless steels can alternatively be categorized as martensitic or semi-austenitic steels.

3mm 316 stainless steel sheet

The paper and textile industries, as well as equipment used in chemical processing, can all benefit from using stainless steel sheet grade 316. Additionally, it is the metal of choice for cutting-edge surgical implants made for the harsh bodily environment.

Austenitic stainless steel sheet grade 316 is distinguished by its 2–3 percent molybdenum content. The addition of molybdenum increases the metal’s resistance to corrosion and pitting as well as its ability to withstand high temperatures.

The typical composition of stainless steel sheet grade 316 is 16 percent chromium, 10 percent nickel, and 2 to 3 percent molybdenum. This boosts corrosion resistance, notably against chlorides and other industrial solvents.

As close to a perfect finish as stainless steel can be created is found on our Stainless Steel Sheet Grade 316. For technical uses like strainers, filters, and sieves in food processing, brewing, and acoustic diffusers as well as for architectural and interior design elements, stainless steel sheet grade 316 can be utilized.

The main benefit of stainless steel sheet grade 316 above grade 304 is its ability to resist gill and gill corrosion in hot chloride environments. The stainless steel sheet grade 316 has demonstrated great resistance in environments that are acidic and demanding, and it is used to make stainless steel cylinders and tanks.

Even at high concentrations and temperatures, stainless steel from the 300 series is resistant to weaker bases like ammonium hydroxide. This is the case even though ammonium hydroxide is a base. However, when exposed to stronger bases like sodium hydroxide, these same steels have a higher risk of etching and breaking. When stainless steel is in touch with other metals in environments that are damp or acidic, galvanic corrosion frequently occurs on the other metals, yet stainless steel itself is frequently unaffected by these conditions.

Stainless steel sheet 316

Coil and sheet made of stainless steel type 316/316L belong to the austenitic family. 316 grades have better corrosion resistance than 304 grades because they contain more nickel than 304 grades. 316/316L sheet is a fantastic option for maritime applications since it has high mechanical qualities at sub-zero temperatures and good corrosion resistance.

In many natural and artificial conditions, stainless steels are more resistant to oxidation and corrosion; however, it is crucial to choose the right type and grade of stainless steel for the intended use.

More than 12% of chromium additions are typically required to obtain high oxidation resistance in air at ambient temperature. When exposed to oxygen, the chromium produces a passivation layer of chromium (III) oxide. The layer is too thin to be seen, thus the metal maintains its shine. However, it is airtight and watertight, shielding the metal below.

Additionally, this layer quickly recovers when the surface is scraped. Materials scientists refer to this occurrence as passivation, which also affects other metals like aluminum. The oxide coating may be scraped off when stainless steel components, such as nuts and bolts, are yanked together, causing the components to weld.

Stainless steel is an excellent base material for a variety of commercial applications due to its resistance to corrosion and staining, ease of maintenance, relative affordability, and well-known shine. The fifteen most popular stainless steel grades are among the more than 150 available.

The alloy is milled into sheets, plates, bars, wire, and tubing for usage as a building material for skyscrapers and other large structures as well as in cookware, cutlery, hardware, surgical instruments, and major appliances, and industrial equipment.

100% of stainless steel can be recycled. In truth, stainless steel is a material that is somewhat environmentally beneficial because more than 50% of new stainless steel is created from recycled scrap metal.

In the construction of buildings, the structural support and tensile strength that steel provides are unparalleled. As a construction material, neither wood nor concrete can compete with steel’s unrivaled durability and strength. Due to the fact that it possesses a wide variety of qualities that are useful in the construction industry, steel is the material of choice.

In the construction of steel buildings, clearspan, modular, and single-slope frames are all common types of frameworks used. Steel has quickly overtaken other building materials as the most preferred alternative due to the relative ease with which it can be constructed and the numerous extra benefits that it provides.

When it comes to building materials, steel is far and away from the best option. Steel is unrivaled when compared to any other material in terms of both its strength and its longevity. Due to the numerous benefits that it provides, steel has been selected as the material of choice for the structural support in the structure.

Steel constructions must have framed structures in order to be valid. Steel construction is frequently regarded as the superior type of construction due to the fact that it requires less time to complete. We are in the steel business with the intention of offering a high degree of quality across the board for all of our steel derivatives, steel semi-finished products, and steel completed products.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@

Your comment submitted.