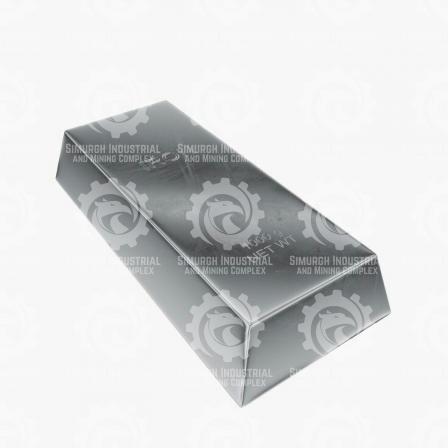

Steel ingots are the first portable and transportable products from steelmaking processes (after iron mining and crude steelmaking) that are solid and portable. In fact, the ingot process is one of the intermediate processes of rolled steels, which is the raw material for downstream industries. Ingots are made by freezing molten metal in molds and serve several purposes. For more information steel ingots trade please visit our website.

Where can You get steel ingots?

The first problem is the shape and size of the billet, which is important in the later stages of the part molding process. The next point concerns the sword in the mold and the solidification of the melt in the mold as this determines the physical and mechanical properties of the final parts. After the transformation of iron ore into crude steel or sponge iron, after steel making and the production of molten steel in the induction furnace or converter, steel ingots are offered as a prefabricated product of different shapes for various uses, types of which can be ingot, billet, bloom and slab pointed out . In the large steel industry, the term steel ingot generally refers to a variety of flowers, billets, or slabs.

The first problem is the shape and size of the billet, which is important in the later stages of the part molding process. The next point concerns the sword in the mold and the solidification of the melt in the mold as this determines the physical and mechanical properties of the final parts. After the transformation of iron ore into crude steel or sponge iron, after steel making and the production of molten steel in the induction furnace or converter, steel ingots are offered as a prefabricated product of different shapes for various uses, types of which can be ingot, billet, bloom and slab pointed out . In the large steel industry, the term steel ingot generally refers to a variety of flowers, billets, or slabs.

The bars also have different qualities such as 3SP-5SP (Russian standard), St37-St52 (German DIN standard), which, despite different percentages of different elements in steel, have different mechanical properties such as flexibility, bending, tensile and torsional ability, as well as applications it requires Variety. Billets or billets are a type of steel bar with a long length and a square or circular cross-section. If the maximum width of the billet is 15 cm and has a cross-sectional area of 230 cm, the flower can be considered as the same billet, which is more than 15 cm wide and has a larger cross-section, as in Figure 2.

Therefore, these will divided into one category for both products. After the molten crude steel is obtained by steelmaking in an electric arc furnace (EAF) or converter, the ingoting process is carried out in two ways: continuous casting and manual casting (single casting). The process of casting and molding ingots is very important because solidification of ingots occurs at this stage and the microstructure (internal order) of the piece is formed here and the physical and mechanical properties of other products also depend on this stage.

The main uses of Bloom and Billet are in the manufacture of beams, wire, rebar (smooth and ribbed), corners and bolts and shields (cloth), seamless pipe and manisman and other sections. For more information steel ingots price please visit our website.

Trade market of steel ingots

Trade market of steel ingots is growing well because this product has many applications and is even exported to other countries, which has a good price, so you can, dear customers. For more information about steel ingots for sale, visit our site.

Trade market of steel ingots is growing well because this product has many applications and is even exported to other countries, which has a good price, so you can, dear customers. For more information about steel ingots for sale, visit our site.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@