Electric furnace and induction furnace method are other methods of converting iron ore to steel. Most of the world’s steel is produced by blast furnace method, but in Iran, electric furnace method is used. For more information about Steel billets Wholesale Market in 2020, visit our site.

What is a steel billets?

steel billets use In the electric furnace method, scrap iron is first poured into the furnace with the help of special baskets and at the same time with the melting of the scrap, a combination of sponge iron and slag-making materials such as coke, bentonite, lime, other additives from the top of the furnace It is added to the melt and after sampling, oxygen is blown (which causes the oxidation of impurities, especially carbon in the melt) and then homogenization and که which is converted to molten steel. In the casting unit, a container called a tandish is poured into a round water copper mold and then converted into a frozen steel ingot by spraying cold water along the roller path.

Finally, the produced slabs are cut to the desired lengths. Sponge iron, which is used in the production of steel ingots, is produced through direct reduction of pellets. The surface ingot is trapezoidal in shape, with a maximum length of 2 meters per branch, and differences in cross-sectional shape and dimensions create types. The capacity of electric arc furnaces varies from one kilogram to twenty tons. For example, Kashan Kavir Steel uses the electric arc method, which has a great difference in price and quality with the products of induction furnace ingots.

Induction furnace can not control oxygen well and this causes defects in the product. Ferroalloy oxidation occurs due to the boiling of dissolved oxygen in the melt. Other problems of induction furnace are desphosphorization and desulfurization. These two operations are performed under two different conditions (high and low temperature of the melt), which is difficult to reduce if both phosphorus and sulfur are high. To solve this problem, it is possible to use a high quality ladle refining furnace, but because these furnaces consume electricity, refractories, electrodes and additives, they are not used in Iranian steelmaking because of the high cost of Follows. Most casting machines are made in China, India or domestically, and their technology is more than thirty years old. Low technology adds poor automation, simple design and… defects to the casting that combine with the defects caused by the analysis in the induction furnace, which is why the quality of the ingots in the induction furnace is low.

As mentioned at the beginning of the article about electric arc furnaces, it should be noted that this furnace produces desirable results due to the possibility of refining the melt. Among the positive features of this furnace is the possibility of producing low carbon ingots, harmful elements such as phosphorus and sulfur in the ingots to a minimum and minimizes the scattering of standard analysis in a consignment.

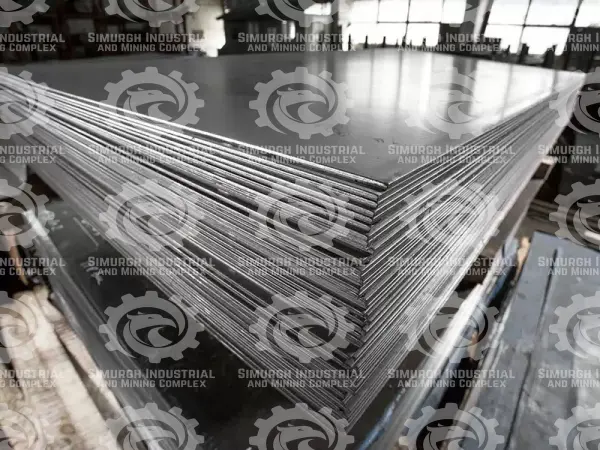

Bulk marketing of steel billets in 2020

One of the important points about the price of steel ingots is that the price of ingots is determined on a daily basis and at first this pricing was done by Khuzestan steel ingots. However, due to the problems that arose in this process, such as the governmental nature of the complex and the lack of transparency in the production prices of this unit, it was decided that the criteria for pricing steel ingots of private producers. For more information about steel billets for sale, visit our site.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@