Bulk non-metallic and semiconductor materials may also be considered as ingots, especially when cast by mold-based methods. It is interesting to know that precious metal ingots can be used as currency (raw and without any other form) or as foreign exchange reserves, such as gold bars, and used in trade and economic exchanges between governments. . For more information about Steel billets Price Fluctuation in 2020, visit our site.

What is difference between ingot and billet?

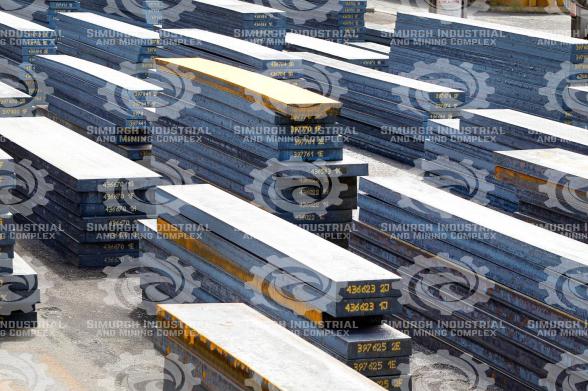

steel billets use are basically pure and unprocessed parts of a particular material that can be used as raw material in the secondary plants where the final product is made and converted and processed.

Of course, ingots are mainly used in connection with metal materials. Ingots are usually produced in alloy or pure after being exposed to high temperatures in certain blocks.

Iron ingots are also produced in the same way and are used in other industries. First, iron ore is extracted from the relevant mines and enters the steel mills, where the impurities of this material are removed by performing activities and The resulting material is cooled in certain molds. Finally, these iron ingots are sent to the market and factories that need this material.

Casting from above requires less labor and consumes less refractory materials, the heat deposition in the ingot mold is improved, the additional contamination due to the contact of the material with the ceramic mold is not produced and the heat of liquid steel and. Is reduced. At the same time, the method of casting from above has some drawbacks, some of which include damage to the wall of the ingot mold, longer casting process, less monitoring of the flow rate of molten material, more wear of the mold, and so on.

In addition, during the process of filling the ingot mold, the material sprays from the mold to the walls of the mold and sticks to it, creating false protrusions on the walls of the ingot mold, which subsequently must be modified over time to Return to the original state. Therefore, the top casting method is not recommended for the production of quality steel products, and the better method is floor casting. In the floor casting method, the molten material is directed from the bottom to the nozzle, which reduces its contact with air and sprays the material to the mold walls.

Price changes of steel billets in 2020

Filling a heavy ingot mold can be done in two ways. The first method is known as casting from above (i) and the second method is called bottom casting (ii). In casting from above, the liquid steel is in direct contact with the air and the problem we will encounter is oxidation. Because the casting current affects the surface of the molten material inside the mold, it contains redox material and powder and floats on the molten material and sinks into the material, affecting its components. For more information about steel billets for sale visit our site.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@