The production of sponge iron by the Midrex method for direct reduction is either based on gas or rock. The use of coal is less considered due to environmental pollution. In Iran, due to the vast gas resources used to regenerate iron ore, it has more economic justification. Midrex is one of the most widely used methods based on gas. Therefore, sponge iron wholesale market this product at a reasonable price.

What is sponge iron why it is called sponge?

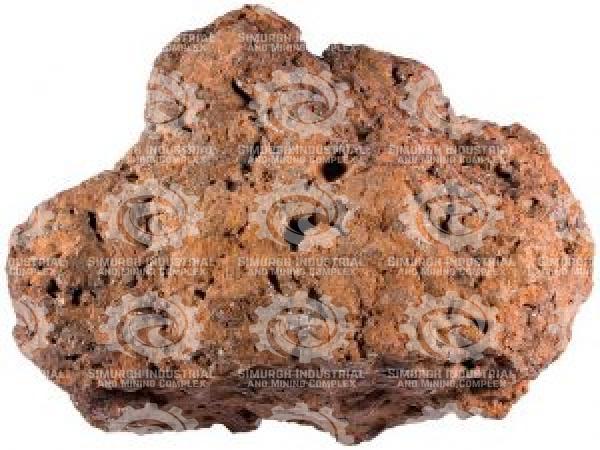

Sponge iron is a metal product that is produced by direct reduction of solid iron ore. In other words, sponge iron is obtained from the direct reduction of iron ore (Direct Reduced Iron).

Iron ore is the pellet that removes its oxygen following a direct reduction process (without intermediaries) and without the need to melt iron ore. Oxygen in iron ore is removed by reducing gases or carbon derived from city gas and coal.

The quality of sponge iron is mainly determined by the percentage of “metallization” (removal of oxygen). The appearance of sponge iron is in the form of spherical pieces (pellets) and because it has a spongy appearance, it is called sponge iron. Sponge iron has a positive effect on the production of steel briquettes and ingots in electric arc furnaces and improves energy consumption, efficiency, efficiency and mechanical conditions of steel ingots.

Sponge iron carat

Foamy iron has a high grade of iron, which is more common today due to the lack of iron waste and increasing its price, as well as environmental problems.

The amount and grade of iron in sponge iron are between 84 to 95%. The high grade of sponge iron makes it a good source for iron and steel production.

Methods of producing snuff iron

- Using natural gas.

- Using thermal coal.

- By means of direct resuscitation of Midrex.

In both methods of producing sponge iron based on gas and coal, to convert iron ore to iron metal (at temperatures below melting point below 1200 ° C) oxygen present in various types of iron ore (iron ore, pellets, concentrate, round And furnace dust and …) is separated.

In fact, the iron produced by the sponge iron reduction process saves energy because it does not require much heat and fuel and the use of traditional furnaces. Sponge iron is converted to steel in electric arc furnaces. sponge iron price is very affordable in our product range.

sponge iron wholesale suppliers

The use of sponge iron is a good alternative to scrap iron, so it is possible to use this material to provide a high percentage of raw materials to provide the required melting to steelmaking units instead of using scrap. One of the most important applications of sponge iron is in induction furnaces. In induction furnaces, it is possible to replace nearly 50% of sponge iron with scrap. Of course, keep in mind that to use it in an induction furnace, technical knowledge and experience are required. In addition, sponge iron has revolutionized the continuous casting of the steel industry. Therefore, sponge iron wholesale suppliers provide these products to customers at reasonable prices.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@