In induction furnaces, 50% sponge iron and 50% scrap iron and sponge iron are used in making iron and steel. This is a good example of the importance of sponge iron. Because this material contains high amounts of iron, it is very important for iron and steel production and preventing environmental problems. It is interesting to know that the grade and amount of sponge iron is between 84% and 95%. For more information on Sponge Iron Price Fluctuation, visit our site.

Unique Characteristics of sponge iron

The price of sponge iron in Iran is rising and falling like other steel products such as iron and steel. These fluctuations may be affected by foreign markets or by the temporary or permanent closure of some production facilities. Scrap iron deficiency and waste can also play a role. These fluctuations can have a major impact on the price of tons of sponge iron or the daily price of sponge iron. For domestic factories, applying for sponge iron exports or sales of high tonnage sponge iron requires timing;

The price of sponge iron in Iran is rising and falling like other steel products such as iron and steel. These fluctuations may be affected by foreign markets or by the temporary or permanent closure of some production facilities. Scrap iron deficiency and waste can also play a role. These fluctuations can have a major impact on the price of tons of sponge iron or the daily price of sponge iron. For domestic factories, applying for sponge iron exports or sales of high tonnage sponge iron requires timing;

Therefore, it is better to consult professional experts before signing a contract or buying the daily price of sponge iron. India is the largest sponge iron producer in the world. Iran is in the next ranks with the increase in sponge iron production. Iran is now one of the world’s largest sponge iron exporters. Due to the steel products chain’s dependence on sponge iron and its use for the smelting and production of steel goods, any change in steel tariffs or market conditions may affect the sponge iron tariff rate. Iran is also affected by global market conditions and fluctuations due to its high tonnage sponge iron exports. Simply put, the sales of sponge iron and fob delivery in country ports are affected by international markets.

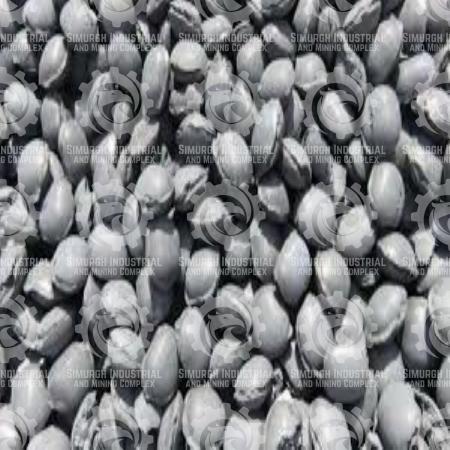

Sponge iron is the product of the direct reduction of iron ore, and in the direct reduction process, its oxygen is removed without the need to smelt the iron ore. Its appearance is in the form of spherical pieces (pellets) or porous sponges, hence the name for its spongy appearance. The reason why iron has a high iron content and the widespread use of sponge iron in the world is the lack of waste and price increase and environmental problems. In English, it refers to Direct Reduced Iron, which means DRI, which means sponge iron.

The main use of sponge iron is for use in induction furnaces for the production of iron and crude steel. By using sponge iron, it is possible to obtain the raw material of steelmaking units and actually replace sponge iron, scrap iron and scrap by about 50%. In addition, the use of sponge iron will cause a major change in the steel industry’s continuous casting. For more information on sponge iron sale, visit our site.

Price changes of sponge iron in 2021

Price changes of sponge iron in 2021 has been due to fluctuations in the foreign exchange market and this product is available to buyers at a good price in our collection. Therefore, you can visit our site for more information about sponge iron trade.

Price changes of sponge iron in 2021 has been due to fluctuations in the foreign exchange market and this product is available to buyers at a good price in our collection. Therefore, you can visit our site for more information about sponge iron trade.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@