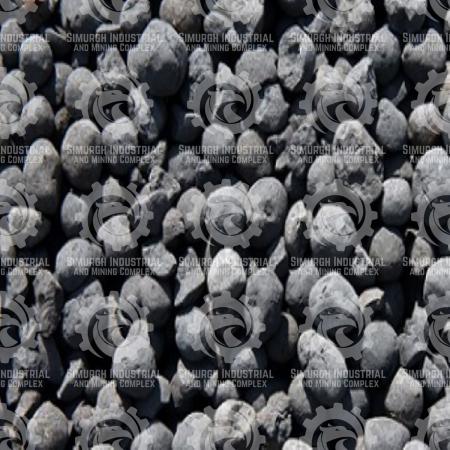

Appearance of sponge iron in the form of porous spherical pieces that have a appearance, which is why it is called sponge iron. Sponge iron has a high iron content, which is more common today due to the lack of scrap iron and the increasing price, as well as environmental problems. Please visit our website for more information about the domestic sponge iron market.

What is sponge iron process?

Sponge iron is a high quality source for the manufacture of iron and steel, recycling natural or processed iron ore without reaching the melting point. In this process, iron ore pellets with a quality of 67% are regenerated and sponge iron is produced by Fe metallization (about 92 degrees). The product manufactured in the reduction unit does not pass through the cooling section of the furnace and is transferred steel making section of the furnace for direct loading by a special material transfer system at a temperature of almost 600 ° C.

Sponge iron is a high quality source for the manufacture of iron and steel, recycling natural or processed iron ore without reaching the melting point. In this process, iron ore pellets with a quality of 67% are regenerated and sponge iron is produced by Fe metallization (about 92 degrees). The product manufactured in the reduction unit does not pass through the cooling section of the furnace and is transferred steel making section of the furnace for direct loading by a special material transfer system at a temperature of almost 600 ° C.

After melting and reducing steel production, in the casting process, sponge iron is the required products and used in three forms: plate, billet and reinforcement. Today around 5% of the world’s steel is made from direct reduced iron, trend is growing. Sponge iron is obtained by direct reduction of iron ore (pellets) and is also known as DRI. Application of sponge iron The use of sponge iron in induction one of the most important applications. It can be said that using sponge iron in induction furnaces can replace scrap by around 50%.

However, application in induction furnaces requires technical knowledge and experience. The use of sponge iron is important development in the continuous casting of the steel industry. It can be used in almost production methods. Many small and large steel making plants in the country use these methods. Iran has more natural resources to reduce directly. Sponge iron is a good to scrap iron. As a result, we can supply a high percentage of raw materials to enable steelmakers to do the smelting they need instead of scrap. The direct reduction of iron ore gas or coal sources. The choice of direct iron ore extraction method depends on the manufacturer’s location and the resources available.

For example, in Iran, despite the rich gas resources, the choice of gas a more sensible choice, and gas is used as a reducing agent. As you know, using coal resources for regeneration also creates problems with air pollution and access to the mines is not easy. Currently, India is the world’s largest producer of sponge iron using the resources of pebbles. You can find more information about the sponge iron plant on our website.

Domestic market of sponge iron

Domestic market of sponge iron that we have produced has been accompanied by good growth and we have been able to export this product to other countries, so you can visit our site for more information about melting point of sponge iron.

Domestic market of sponge iron that we have produced has been accompanied by good growth and we have been able to export this product to other countries, so you can visit our site for more information about melting point of sponge iron.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@