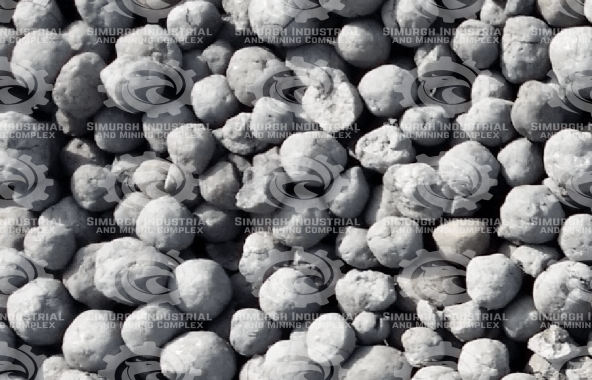

The direct oxidation-reduction of iron ore (in the form of lumps, pellets, or debris) to iron results from the reduction gas or elemental carbon produced from natural gas or coal. Many minerals are suitable for direct reduction. Direct reduction refers to solid state processes that reduce iron oxides to metallic iron at temperatures below the melting point of iron. Reduced iron gets its name from these processes, an example of which is heating iron ore in a furnace at temperatures above 800 to 1200 ° C (1470 to 2190 ° F) in the presence of a synthetic gas reducing agent, a combination of hydrogen and carbon monoxide. . For more information about Sponge iron Distribution centers, visit our site.

What is sponge iron used for?

Sponge iron is a good alternative to scrap iron, so it can be used to provide a high percentage of raw materials to provide the required melting to steelmaking units instead of scrap. It is one of the most important applications in induction furnaces.

In induction furnaces it is possible to replace scrap by about 50%.

Of course, keep in mind that to use it in an induction furnace, technical knowledge and experience are required. In addition, sponge iron has revolutionized the continuous casting of the steel industry.

In Iran, the use of sponge iron in induction furnaces began in 2010 in one of the factories in Yazd. Of course, at that time, because the amount of scrap iron, although of low quality, was very high; The need to use sponge iron did not seem necessary. On the other hand, the initial experiences of sponge iron applications were not very desirable; Because of not knowing the proper methods, the melting time was long and terrible slag was obtained.

With the increase of knowledge and improvement of melting methods, today the problems of using sponge iron instead of scrap iron have been minimized and this product is used in many small and large steelmaking units.

Oxidation and corrosion are the dangers of sponge iron; Therefore, it should be protected and turned into steel as soon as possible. Other dangers of sponge iron include the possibility of ignition in the paste state.

To prevent the oxidation of sponge iron, this product can be protected by neutral gas, sodium silicate, lime and then placed indoors and briquettes. For more information about sponge iron formula, visit our site.

Distributing sponge iron in bulk

The melting point of sponge iron, or the degree of ironing, is actually the amount of free iron in sponge iron. If the degree of metallization of sponge iron is 91% and the total iron in sponge iron is 91%, the product of these two numbers is the amount of iron present in sponge iron in pure form. For more information about Distributing sponge iron in bulk, visit our site.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@