The direct reduction process is one of the new methods of iron production in which iron is produced without the use of a coking process, or in some cases without the formation of lumps. The direct reduction of iron oxides with carbon has been extensively studied in recent decades. For more information on Pig Iron Wholesale Supplier, visit our website.

What is pig iron made of?

Over the last thirty years, a new technology called direct reduction process has been developed to reduce iron ore to ferrous metal using coking coal or natural gas. Economic issues and environmental impacts have provided the necessary impetus for research and development on this process. The process of direct reduction at temperatures below the melting point temperature removes oxygen from the iron ore and makes its structure porous. For this reason, this product is known as sponge iron and generally contains between 92% and 96% pure iron.

Over the last thirty years, a new technology called direct reduction process has been developed to reduce iron ore to ferrous metal using coking coal or natural gas. Economic issues and environmental impacts have provided the necessary impetus for research and development on this process. The process of direct reduction at temperatures below the melting point temperature removes oxygen from the iron ore and makes its structure porous. For this reason, this product is known as sponge iron and generally contains between 92% and 96% pure iron.

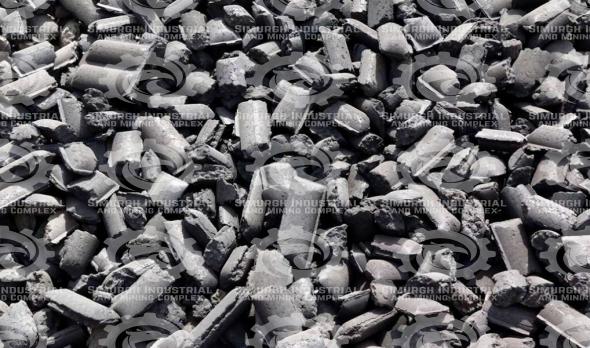

Sponge iron can be used as a raw material for the production of steel, for example, in electric summer furnaces. The direct reduction process is generally divided into two groups according to the type of reduction used. Coal-based direct reduction processes in which a carbon reducing agent, usually coal, is used. Gas-based direct reduction processes using a gas reducing agent. The choice of one of the two methods depends on the location of the manufacturer and the available sources. In the first type of process, coking coal is generally used as a reducing agent.

Technologies that use this method for renewal include rotary kiln-based processes such as SL / RN and rotary bed kiln-based processes such as Fastmet. The advantages of these methods are the use of high quality coking coal, low commissioning and operating costs, low operating temperatures and energy savings compared to high furnaces. In the second type of process, natural gas is used to separate oxygen from iron oxides. These processes prefer coal-based processes in areas where natural gas resources are affordable. They also cause less pollution.

Common methods used in gas reducers include Midrex and Achival processes. Today, more than 8% of the world’s iron needs are obtained through the direct reduction process with the help of coal. However, research is ongoing in this area to increase efficiency, reduce energy consumption, improve product quality, and completely improve the recovery process. For more information pig iron weights visit our website.

Bulk suppliers of pig iron in 2021

Our company is one of the Bulk suppliers of pig iron in 2021 and exports this widely used product to European countries, which has both good quality and reasonable prices that you can For more information about pig iron price, visit our site.

Our company is one of the Bulk suppliers of pig iron in 2021 and exports this widely used product to European countries, which has both good quality and reasonable prices that you can For more information about pig iron price, visit our site.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@