Sales of magnetite concentrate iron ore exported by analyzing 67% Fe at a rate of 28% FeO below 2 with low harmful elements (phosphorus and sulfur values lower than 0.08% and 0.05%), at a tonnage of 30,000 tonnes per day, by SIMURGH iron and steel company. The place of delivery is mine. Due to the volatility of the iron ore price rate and the likelihood of momentum fluctuation in the world market for iron ore price, and of course the change in logistics costs, including shipping, we consider the final validity of the iron ore concentrate price to be 3 business days. The source of the announcement is the news of iron ore prices on the PLATTS iron ore site.

Iron concentrate supply co

An examination of the annual volume of iron ore concentrate exports to China, India, etc. indicates that exports to China are high. Statistics show that China ranks highest among Iran’s export iron ore export targets.

The annual volume of iron ore concentrate exports from our ports, especially the port of Chabahar, reaches several million tons per year. Statistics show that these cargoes are destined for countries such as China, India, and others. Iron ore concentrate export data for the first six months of last year (year 2) showed exports of more than three million tonnes worth more than $ 326 million. The source is the Customs Statistics of the Islamic Republic of Iran.

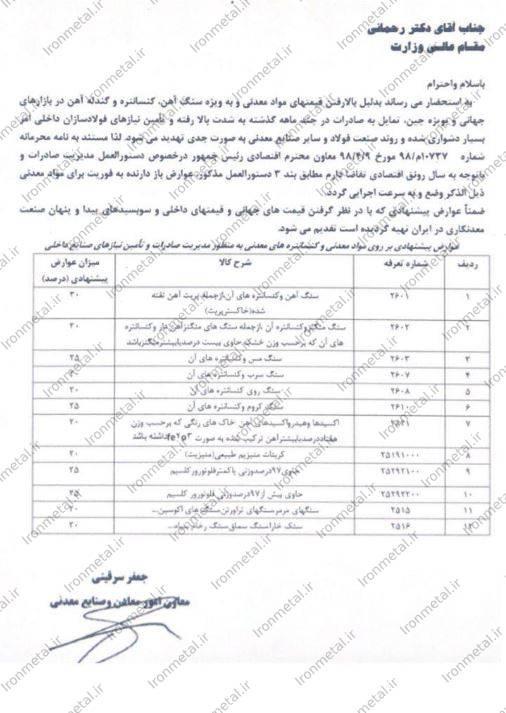

Of course, Iran’s foreign trade and export laws aimed at controlling the domestic market and supplying the required product to domestic steel mills have recently undergone changes by the Ministry of Industry and Mining that will likely affect export statistics. According to the latest section of the letter, export duties have been applied to exports of iron ore, iron ore concentrate and pellets. The picture of the issued circular is shown below.

According to this directive, 30 percent of the tariff has been applied to exports of iron ore, iron ore concentrate and iron ore pellets. The decision was made in the wake of a problem for large factories such as Isfahan’s Mobarak Steel and Isfahan’s steel mills to provide raw materials to support domestic production. But it is hoped that with the proper management of the relevant organs, export support will also be on the agenda.

Of the raw materials and intermediates of the iron and steel industry, only sponge iron can currently be exported without any export implications.

iron ore concentrate price

The global price of iron ore concentrate is the most important indicator for determining and announcing the export price of Iranian iron ore in our ports such as Chabahar Port and Imam Port. In determining export rates and in international transactions most of the global indices such as metal bulletin and platts are taken into account.

Iron ore concentrate index

You can see the daily iron ore price update and iron ore concentrate price on the iron ore price announcement page. These rates are Simorgh’s index day rate based on global estimates and Iran’s logistics costs as per the latest day trading in ports. You can see the iron ore daily price chart for October 5 in the table below. Updates will be made on the day rate page.

| Shipping C. | W. Change | D. Change | CFR China | FOB BND | Spec | Purity | Products |

| ۲۹٫۰$ | -۱۷٫۷% | ۵٫۰$ | ۶۱٫۶$ | ۳۲٫۶$ | ۶%Si,2%Al,0.2%P,0.2%S | ۶۰% | Iranian hematite fines |

| ۲۹٫۰$ | -۲۴٫۱% | ۴٫۰$ | ۴۷٫۹ | ۱۸٫۹$ | ۶%Si,2%Al,0.2%P,0.2%S | ۵۵% | Iranian magnetite fines |

| ۲۹٫۰$ | -۱۷٫۰% | ۵٫۰$ | ۶۳٫۱$ | ۳۴٫۱$ | ۶%Si,2%Al,0.2%P,0.2%S | ۶۱% | Iranian hematite fines |

| ۲۹٫۰$ | -۱۵٫۶% | ۵٫۰$ | ۶۵٫۸$ | ۳۶٫۸$ | ۶%Si,2%Al,0.2%P,0.2%S | ۶۲% | Iranian hematite fines |

| ۲۹٫۰$ | -۲۶٫۳% | ۴٫۰$ | ۴۷٫۲$ | ۱۸٫۲$ | ۶%Si,2%Al,0.2%P,0.2%S | ۵۶% | Iranian hematite fines |

| ۲۹٫۰$ | -۲۳٫۱% | ۴٫۰$ | ۴۹٫۰$ | ۲۰٫۰$ | ۶%Si,2%Al,0.2%P,0.2%S | ۵۷% | Iranian hematite fines |

| ۲۹٫۰$ | -۶۶٫۵% | ۴٫۰$ | ۵۱٫۴$ | ۲۲٫۴$ | ۶%Si,2%Al,0.2%P,0.2%S | ۵۸% | Iranian hematite fines |

| ۲۹٫۰$ | -۱۶٫۴% | ۵٫۰$ | ۶۴٫۷$ | ۳۵٫۷$ | ۶%Si,2%Al,0.2%P,0.2%S | ۶۰% | Iranian magnetite fines |

| ۲۹٫۰$ | -۱۹٫۹% | ۴٫۰$ | ۵۳٫۱$ | ۲۴٫۱$ | ۶%Si,2%Al,0.2%P,0.2%S | ۵۹% | Iranian hematite fines |

| ۲۹٫۰$ | -۱۵٫۸% | ۵٫۰$ | ۶۶٫۲$ | ۳۷٫۲$ | ۶%Si,2%Al,0.2%P,0.2%S | ۶۱% | Iranian magnetite fines |

| ۲۹٫۰$ | -۱۵٫۳% | ۵٫۰$ | ۶۷٫۷$ | ۳۸۰٫۷$ | ۶%Si,2%Al,0.2%P,0.2%S | ۶۲% | Iranian magnetite fines |

| ۲۹٫۰$ | -۲۵٫۱% | ۴٫۰$ | ۴۶٫۹$ | ۱۷٫۹$ | ۶%Si,2%Al,0.2%P,0.2%S | ۵۴% | Iranian magnetite fines |

| ۲۹٫۰$ | -۲۲٫۸% | ۴٫۰$ | ۴۹٫۳$ | ۲۰٫۳$ | ۶%Si,2%Al,0.2%P,0.2%S | ۵۶% | Iranian magnetite fines |

| ۲۹٫۰$ | -۲۱٫۴% | ۴٫۰$ | ۵۱٫۰$ | ۲۲٫۰$ | ۶%Si,2%Al,0.2%P,0.2%S | ۵۷% | Iranian magnetite fines |

| ۲۹٫۰$ | -۲۰٫۰% | ۴٫۰$ | ۵۳٫۰$ | ۲۴٫۰$ | ۶%Si,2%Al,0.2%P,0.2%S | ۵۸% | Iranian magnetite fines |

| ۲۹٫۰$ | -۱۸٫۰% | ۴٫۰$ | ۵۶٫۴$ | ۲۷٫۴$ | ۶%Si,2%Al,0.2%P,0.2%S | ۵۹% | Iranian magnetite fines |

| ۲۹٫۰$ | -۲٫۱% | ۴٫۰$ | ۹۳٫۸$ | ۶۸٫۸$ | ۰٫۱%P, 0.2%S,6%Moisture | ۶۷% | Iranian concentrates |

| ۲۹٫۰$ | -۸٫۰% | ۴٫۰$ | ۹۲٫۵$ | ۶۳٫۵$ | ۰٫۱%P, 0.2%S,6%Moisture | ۶۶% | Iranian concentrates |

| ۲۹٫۰$ | -۸٫۲% | ۴٫۰$ | ۹۰٫۲$ | ۶۱٫۲$ | ۰٫۱%P, 0.2%S,6%Moisture | ۶۵% | Iranian concentrates |

Current market price of iron ore concentrate

Given the importance of the Chinese market in global trading of iron ore and iron concentrate, the Dalian china commodity exchange is very important in setting global rates. The index shows a downtrend in the latest changes on 20 October 2019. In compiling and reviewing weekly changes, we saw a -7% drop for the World Iron Ore Index. This announced in metal bulletin iron ore index as well as PLATTS iron ore index. We announce the origin of this decline in the following two cases, including:

- Growing inventories ports in China to about + 8%

- Government imposes steel restriction on Chinese steel mills aimed at controlling air pollutant entry

The high importance of China’s steel and iron ore market and the high impact of its volatility on world prices is due to the high import of iron ore into China. In fact, China is the largest importer of iron ore in the world. Iron ore price index in the Chinese Dalian Stock Exchange is an important index and parameter in determining and predicting future price fluctuations in the world market as well as Iran export iron ore market.

Global price indices of iron ore, iron concentrate, and iron ore pellets have shown a significant and then declining growth since the beginning of the year, creating a peak in the price chart. The price jump followed a sharp decline in exports by the world’s largest iron ore exporters. As you know, the Brazilian whale companies, Riotinto and BHP are the largest exporters of iron ore in the world. Unfortunately, force majeure problems for these exporters led to a marked decline in supply-side demand in world markets, including Chinese ports, which subsequently led to growth and iron ore price index. Force Majeure conditions for the Brazilian Valle Company occurred due to the breaking of several tailings barriers. For Riotinto and BHP companies based in Australia, it was also caused by the storm of Veronica. As you can see in the chart below, the iron ore price fluctuation has been increasing over the period from December 2018 to August 2019. But since August until now, in October, rates have fallen and even returned to pre-crash prices for the Brazilian tailings dam.

Here’s a brief explanation of why rates are returned:

The most important reasons for the price declines and the declining trend have been the two major declines in steelmaker margin and the reversal and increase in exports of iron ore and concentrate by the largest exporters, Brazil and Australia.

- Declining profit margins for steelmakers are factors in the pressure on price rates. With falling margin profits we often see prices drop. What has happened recently has been the price pressure.

- Increasing the supply and export capacity of the world’s largest iron ore exporting companies has given a signal to the iron ore buyers that they are seeking discounts from exporters. Most of the Brazilian and Australian exporters responded positively because of the increased supply capacity.

These two events led to a drop in prices.

67% iron ore concentrate price

Below you will find the analysis of the three grades of iron concentrate available in the mines and sites of Azarbaijan Iron and Steel Company. The monthly supply capacity may vary over the months due to changes in delivery obligations to customers and buyers. To inquire about the purchase price for each grade of iron concentrate, please contact the sales department first and after receiving the approval of Commerce Manager Ms. Nematzadeh you can finalize your order.

| 68.48 | % | Fe |

| 68.46 | % | Fe2O3 |

| 26.36 | % | FeO |

| 1.28 | % | SO3 |

| <0.06 | % | P2O3 |

| 0.64 | % | CaO |

| 0.05 | % | K2O |

| 1.29 | % | MgO |

| 0.17 | % | Na2o |

| <1.41 | % | Al2O3+SiO2 |

| <9 | % | TiO2 |

| <0.1 | % | L.O.I |

| – | Cm2/gr | SG |

|

|

||

| 67=< | % | Fe |

| – | % | Fe2O3 |

| 28=< | % | FeO |

| <0.05 | % | S |

| <0.08 | % | P |

| <1 | % | CaO |

| – | % | K2O |

| – | % | MgO |

| – | % | Na2o |

| <4.2 | % | Al2O3+SiO2 |

| – | % | TiO2 |

| – | % | L.O.I |

| 1600< | Cm2/gr | SG |

| 65.84 | % | Fe |

| 23.36 | % | FeO |

| 0.203 | % | S |

| 0.061 | % | P |

| 0.41 | % | CaO |

| 0.05 | % | K2O |

| 1.65 | % | MgO |

| 0.2 | % | Na2o |

| <4 | % | Al2O3+SiO2 |

| 0.32 | % | TiO2 |

| – | % | L.O.I |

| – | Cm2/gr | SG |

If you are considering purchasing iron concentrate for export, please contact our business management directly to review your purchase request.

Dry concentrate iron ore

Iron ore fines

Iron concentrate is processed from low purity iron ore. In mines and iron ore extraction sites, in addition to high purity iron ore, some of the extracted iron ore has lower purity. The crude iron ore obtained from high purity is often processed dry in the form of granular iron ore. The granulated iron ore itself is classified into fine aggregates and lumps types (iron ore fines and iron ore lumps). These two products are directly used for melting in the long furnace.

Iron ore concentrate plant

Low-purity crude iron ore often cannot be purified only by dry aggregation and requires washing and concentration. It must therefore undergo a specific process known as concentrate. The process consists of the following steps:

- Crushing step, the first step of concentrating.

- Milling the second step of concentrating.

- Increase the purity of the third step of concentrating.

- Dehydration of the four concentrates.

You can read the following article for a more detailed study of each step of the concentrate process.

Due to the low iron purity in the ore deposits, after iron ore extraction, iron ore purity is increased during the concentrating process. Iron concentrate is the by-product of the ore mining plant. The process of concentrating involves several stages including crushing, grinding, concentration and dehydration. We briefly describe each step in the text below.

[toggle title=”iron ore concentrate plant” state=”close”]

Due to the low iron purity in the ore deposits, after iron ore extraction, the iron ore is increased during the concentrating process. Iron concentrate is the by-product of the ore mining plant. The process of concentrating involves several stages including crushing, grinding, grinding and dehydration. We briefly describe each step in the text below.

-

-

- Crushing stage, the first stage of concentrating: The material and the primary product of this section is the deposit between 20 and 25 cm to 100 cm. At this stage, the crushing process of iron ore is carried out in gyratory or general crusher and in the second stage in conical crusher. The product of this step is a mineral of less than 30 mm.

- Milling, the second stage of concentrating: The milling process is performed to reduce the dimensions of the minerals to below 30 mm. It is a more process. Asbestos and semi-crusher Asiatically, then the size of the grains reaches about 0.5 to one millimeter.

- Increasing the purity of the third stage of concentrating: In this section valuable high-grade iron grains are separated from the tailings. This process is performed during more magnetic separation steps and if needed flotation. The flotation process is based on the physical and chemical properties of the materials. The high-speed process involves both the magnetic process and the flotation process in the aquatic environment. So high iron ore is wet and requires dewatering on the product to reach below 10% moisture.

- Dehydration of the four concentrates: It is used to reduce the moisture content of the concentrate and in fact to dehydrate the filter. So the concentrate is transferred to the depot for storage with a moisture content of about 9 to 10 percent.

-

Iron concentrate fins are not directly usable. Not in a blast furnace and direct reduction not. So how is iron concentrate used? In fact, iron concentrate is the raw material of the pelletizing unit.[/toggle]

Hematite iron ore concentrate

An additional explanation for the iron ore concentrate is its type, which is often classified into two groups: magnetite iron ore and hematite iron ore concentrate. The iron ore product used for concentrating can be either hematite or magnetite. The discrepancy between these two types of iron ore and the different uses of concentrate, which is sometimes for non-steel chains, may cause some buyers and customers to request a specific type of registration.

hematite iron ore 58 fe price

Hematite and magnetite iron ore aggregates are sold from 0 to 10, 0 to 20 as well as 10 to 30. The cargo analysis is included in the catalog of Simorgh Steel Company which can be downloaded from the link below.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@