Pellets are different types of steel that are used to make iron ore steel. Pellets are pellets made from finely chopped iron ore that are used in direct reduction or in the blast furnace to produce iron. For the production of this type, iron ore is one of the most important raw materials and for the production of pig iron in reduction furnaces it must have the desired mechanical, chemical and thermal properties. To produce the raw pellet, the iron ore, which contains additives (90% of it below 325 mesh or 45 microns), must be rotated in the pelleting machines with water-wetting solutions to obtain a spherical shape so that the raw pellet is finally produced. Please visit our website for more information on iron pellets wholesale in 2021.

What is the difference between iron pellet and sinter?

However, additives and adhesives such as calcium hydroxide can be added during the production of raw pellets in order to increase the quality and mechanical metallurgical properties. At this stage, the pellets with the desired dimensions and sufficient mechanical strength are produced and transported to the hardening or baking machine. In the next step, due to the hardening in the oxidizing atmosphere, the raw pellets are carefully heated in a drying and cooking machine to a temperature below the softening temperature of iron ore; Of course, this step is carried out until the degree of porosity of the pellets is not reduced.

However, additives and adhesives such as calcium hydroxide can be added during the production of raw pellets in order to increase the quality and mechanical metallurgical properties. At this stage, the pellets with the desired dimensions and sufficient mechanical strength are produced and transported to the hardening or baking machine. In the next step, due to the hardening in the oxidizing atmosphere, the raw pellets are carefully heated in a drying and cooking machine to a temperature below the softening temperature of iron ore; Of course, this step is carried out until the degree of porosity of the pellets is not reduced.

In the next step, the bond between the iron ore particles and other pellet materials changes, the crystal structure of the rock changes and reactions between the slag material and the iron oxides take place. First, the materials are exchanged with each other and neutral compounds or bases are formed between the grains of iron oxides. In the final stage of cooking, the hot pellets should be cooled down so that turkey does not form in the pellets. Lump feed in industries consisting of iron ore with a grain size of less than 10mm (6mm) is used for blast furnaces and direct reduction plants.

This material combines with the initial load of the clogging machine in the blast furnace and after grinding can be added to the initial load of the pellet for direct reduction. Lump feed is better suited to use in pelletizing than pellet feed, which we will discuss below. Lump feed is easier to transport than pellet feed. The relative losses of piece feed are lower during transport. No special transport equipment is required for clumping. For more information on the iron pellets properties please visit our website.

Bulk supplying of iron pellets in 2021

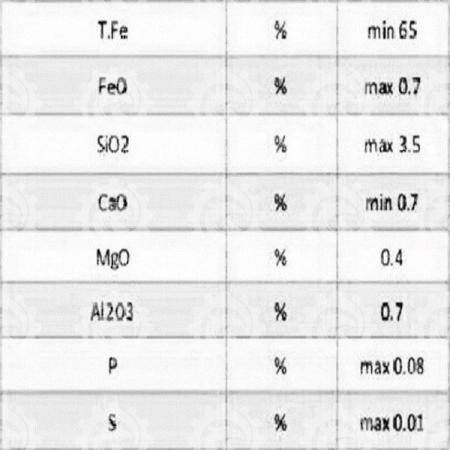

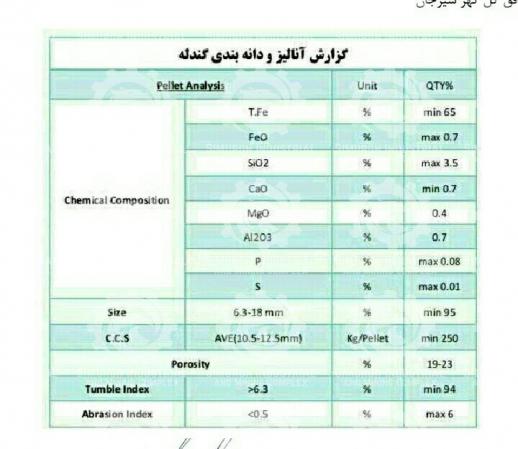

Bulk supply of iron pellets in 2021 is possible by our company and we deliver this product to the customer at different prices, which is of good quality, so you can For more information about iron ore pellet specifications, visit our site.Bulk supply of iron pellets in 2021 is possible by our company and we deliver this product to the customer at different prices, which is of good quality, so you can For more information about iron ore pellet specifications, visit our site.

Bulk supply of iron pellets in 2021 is possible by our company and we deliver this product to the customer at different prices, which is of good quality, so you can For more information about iron ore pellet specifications, visit our site.Bulk supply of iron pellets in 2021 is possible by our company and we deliver this product to the customer at different prices, which is of good quality, so you can For more information about iron ore pellet specifications, visit our site.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@