Iron ore particles are extracted from iron ore concentrate. Iron concentrate is a surface iron ore that cannot be used in melting equipment and even in direct reduction units due to its size. Therefore, iron concentrate is converted to particles after processing. The obtained iron particles can be used in melting equipment and direct reduction units. Visit our site for more information about iron ore pellets.

What is the difference between pellet and sinter?

Sponge iron is a product of the direct renewal of iron particles. The iron ore particles are restored without melting. The resulting product is a sponge iron piece. The foam, along with iron scrap, is used in furnaces that melt in steel mills and turns into ingots (tickets). Iron and steel trading companies can clean raw steel products in very favorable conditions if there is a lot of raw material supply.

Sponge iron is a product of the direct renewal of iron particles. The iron ore particles are restored without melting. The resulting product is a sponge iron piece. The foam, along with iron scrap, is used in furnaces that melt in steel mills and turns into ingots (tickets). Iron and steel trading companies can clean raw steel products in very favorable conditions if there is a lot of raw material supply.

Therefore, the supply capacity of these companies is, of course, very high in terms of the price of sponge iron or other intermediate steel products. Especially if the company is also working in the export sector, due to its very high purchasing power, the very high capacity of iron concentrate, iron particles, sponge iron, granulated iron ore and so on can be recalled and widely available to customers. In appearance, the sponge iron particles are round and round in shape, resulting in the restoration of the iron ore.

It is used in the steel and iron industries and is a good alternative to iron breaking. The sponge is produced by iron, natural gas, and thermal coal, as well as by a direct reduction in midrex. Using this product will reduce energy consumption. The amount of sulfur and phosphorus in this product is very low and there is a lot of work on iron and metal. Dirt, rust and fire can be the hallmarks of this product, but in general, it should be noted that it has many advantages over iron, including that it can be easily stored and protected during nitrogen and can consume less energy. iron.

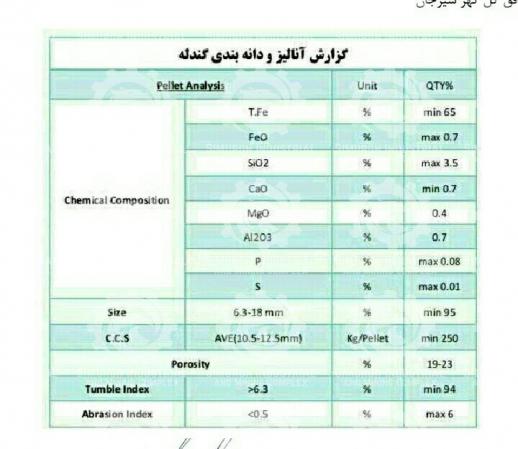

The production of low-carbon sponge iron by the Midrex method is very frequent in terms of high efficiency and can actually be said to be quite efficient. The daily price of the best sponge iron particles depends on the conditions in the iron and steel market. Of course, you have to keep in mind that the price of low-carbon steel particles is concentrated or slightly different, and if the price of steel in the market stabilizes, the price of iron particles will be determined and stable. The purity of the sponge iron particles is sixty-nine percent and is used for induction furnaces and electric bows. This product is used for direct blast furnaces. Visit our site for more information on iron ore pellets chemical composition.

Annual sales growth of iron ore pellets

Annual sales growth of iron ore pellets is very good and suitable and is also exported to Asian and European countries, which is also of high quality, so you can For more information about iron ore pellets market, visit our site.

Annual sales growth of iron ore pellets is very good and suitable and is also exported to Asian and European countries, which is also of high quality, so you can For more information about iron ore pellets market, visit our site.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@