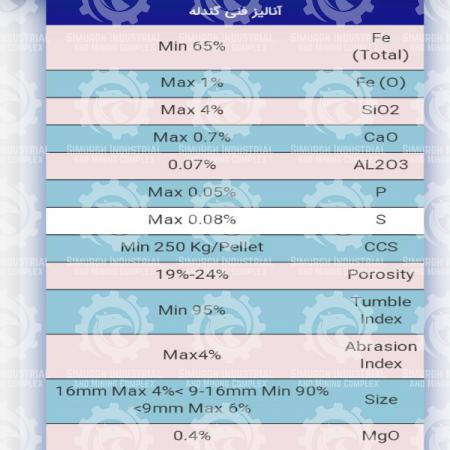

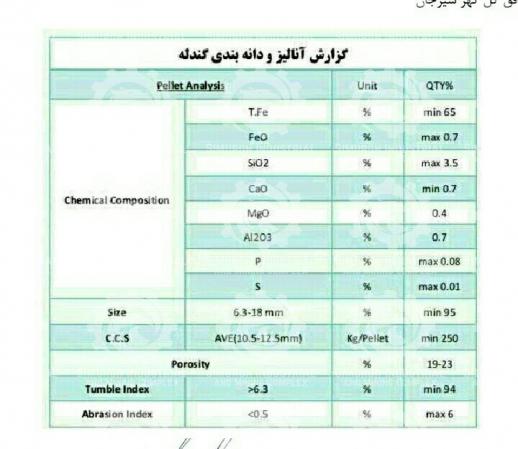

Small pellets made from iron ore and other additives that are hard or cooked. Pellets used in the direct reduction method have more iron scales and less impurities than blast furnace pellets. The pellets used in the blast furnace should have a larger size and higher strength, which also depends on the size of the blast furnace. The rate of regeneration also depends on the degree of porosity, the contact surface and the solid contact of the gas. Therefore, for more information on Iron ore pellets profit growth visit our site.

What is iron ore pellets?

For the production of this product, crushed and ground iron ores with a grain size between zero and one hundred micrometers are supplied worldwide as pellet feed. equipped with pelletizers are considered suitable loads and hardened pellets are also used. The raw materials for production include: Bentonite Lime milk Organic material cement water First, the raw materials are poured into the pelleting machine in a certain ratio.

For the production of this product, crushed and ground iron ores with a grain size between zero and one hundred micrometers are supplied worldwide as pellet feed. equipped with pelletizers are considered suitable loads and hardened pellets are also used. The raw materials for production include: Bentonite Lime milk Organic material cement water First, the raw materials are poured into the pelleting machine in a certain ratio.

The reason for adding each of the additives is not more than two factors of improving mechanical properties and metallurgical properties. The most important mechanical properties are remarkable in their mechanical strength. Adhesion of raw materials to one another and facilitates regeneration in the blast furnace. Efforts should be made to bring the quality of iron ore used in raw materials closer to the limit of 69% hematite or 72% magnetite. Energy sources are saved through the consumption of high-quality ore. In general, the production methods are divided into two methods: the cone method and the disc method.

Until the early 1950s, the only method was the same cone method, which gradually became the main production method for discs on an industrial scale as technology advanced. To return low quality iron ore to the production cycle, we use the concentrate process. In this way, with advanced methods, impure and harmful elements of the stone are picked up and it takes on an integrated form inside and out.

These processes include the steps of grinding, milling, upgrading and dewatering. The concentrate obtained from iron ore is first converted into pellets and then into steel. Pellets made from iron ore and other additives are called pellets, and the process of converting raw material particles into these dense masses is called pelletization. For more information iron ore pellet specifications on the please visit our website.

Profit growth of iron ore pellets

Profit growth of iron ore pellets is significantly increased so that the price of this product is very affordable and this product has many applications that have led to more sales growth, so you can for information See more about types of iron ore pellets on our site.

Profit growth of iron ore pellets is significantly increased so that the price of this product is very affordable and this product has many applications that have led to more sales growth, so you can for information See more about types of iron ore pellets on our site.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@