China, the world’s largest producer, consumer and importer of iron ore, produced 1.3 billion tons of iron ore in 2012, accounting for about 44 percent of the world’s gross domestic product. However, the iron output of low-quality Chinese iron ore contains 22% iron. More than half of the country’s GDP comes from mines in Hebei and Liaoning provinces, while Beijing, Shanxi, and iron ore pelletsare in other areas of iron ore production.

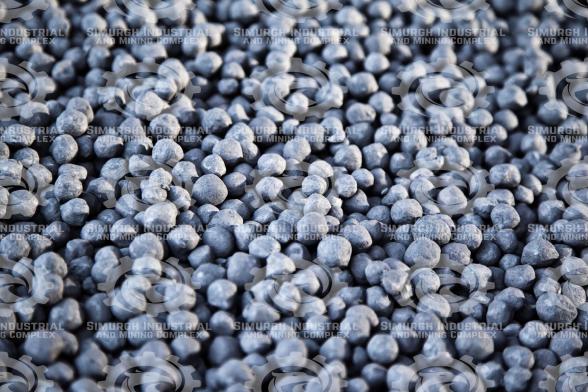

Iron ore pellets unique specifications

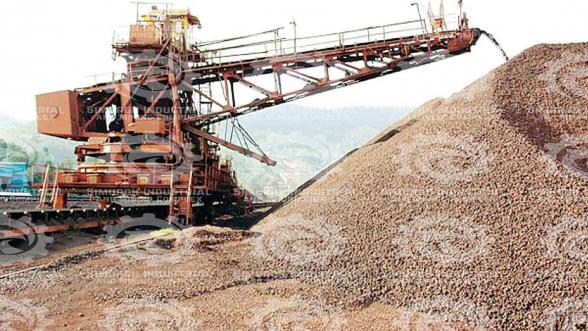

Iron ore crushing is now mostly done in iron ore processing workshops and in self-braking and semi-self-breaking Asian countries instead of classical Asia (rod-pellet). In autochthonous Asians, the extracted stones enter autochthonous Asia directly after the first stage of crushing, and the coarse grains crush other particles as they break down. In this way, these Asians can replace the second and third stage crushers, which we are practically forced to use in the crushing section. These Asians have a very high crushing coefficient and produce large products with dimensions of about 1 mm by accepting large stones (300 to 500 mm).

Iron ore crushing is now mostly done in iron ore processing workshops and in self-braking and semi-self-breaking Asian countries instead of classical Asia (rod-pellet). In autochthonous Asians, the extracted stones enter autochthonous Asia directly after the first stage of crushing, and the coarse grains crush other particles as they break down. In this way, these Asians can replace the second and third stage crushers, which we are practically forced to use in the crushing section. These Asians have a very high crushing coefficient and produce large products with dimensions of about 1 mm by accepting large stones (300 to 500 mm).

With the use of self-breaking Asia, the crushing work of one or two stages of crushing (second and third stage iron ore pellets price) and at least one rod Asia and even a part of the work of a pellet Asia can be done completely, and in this way at least one can It reduced investment costs by about 20 percent. The existence of self-breaking Asia saves on the current cost of crushing iron ore, and the amount of current cost savings reported by self-irony ore pellets price Asia is about 15 to 20 percent.

Manufacturing process of iron ore pellets

Most iron ore ore crushing and crushing products are used to produce pellets, and as a result, the output of the self-braking or semi-self-breaking mill is larger than the desired level for pelletizing (about 40 to 50 microns). As mentioned, soft crushing is not cost-effective in these Asian countries, because for soft crushing, the Asian erosion operation must be strengthened, so for further crushing, the output of self-braking Asia enters the ball mill (with relatively small pellets). Since most of Iran’s iron ore is used by steel production units.

Most iron ore ore crushing and crushing products are used to produce pellets, and as a result, the output of the self-braking or semi-self-breaking mill is larger than the desired level for pelletizing (about 40 to 50 microns). As mentioned, soft crushing is not cost-effective in these Asian countries, because for soft crushing, the Asian erosion operation must be strengthened, so for further crushing, the output of self-braking Asia enters the ball mill (with relatively small pellets). Since most of Iran’s iron ore is used by steel production units.

It is magnetite, so the use of a ball mill for soft crushing with magnetic inner coating can be an interesting solution for advanced crushing. In this type of liner, there is usually a permanent magnetic layer between the outer steel cover of Asia and the liner and rubber, and in the volume of the rubber liner, permanent magnets are evenly distributed. This causes the rubber ester to stick to the wall, so the installation of the liner does not require bolts and nuts. On the other hand, the presence of magnetism in the Asian interior iron ore pellets market absorbs the soft magnetic particles (magnetic iron ore) on the cover and It protects against corrosion and erosion, and thus the protective layer that forms on the lining will be an important factor in the life of the interior coating.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@