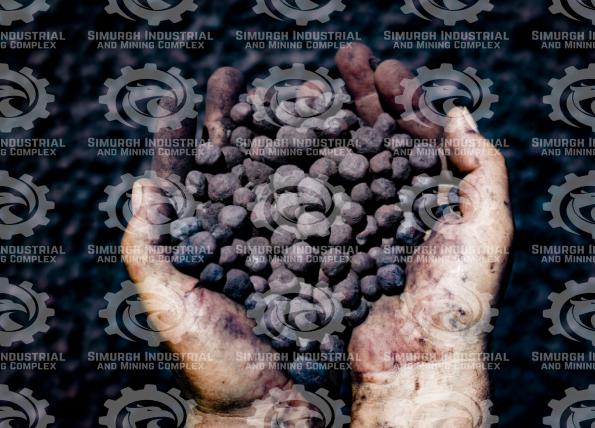

iron ore in pellet many uses in various fields. Due to its high strength and resistance to metal size, as well as being cheaper, it is used in industrial machinery, transportation equipment, construction of structures, large ship hulls and automobile manufacturing. It should be noted that of the types of iron (mentioned above), beams and rebars are the most used in construction.

How are iron ore pellets made?

The direct regeneration process is generally divided into two groups based on the type of regenerator used.

The direct regeneration process is generally divided into two groups based on the type of regenerator used.

- Direct coal-based regeneration processes in which a carbon regenerator, usually coal, is used.

- Gas-based direct reduction processes, in which a gas regenerator is used.

The choice of one of two methods depends on the location of the manufacturer and the available resources. In the first type of process, coking coal is usually used as a reducing agent. Technologies that use this method for regeneration include kiln-based processes such as SL / RN and rotary-based kiln-like processes such as Festmet. The disadvantages of using high-quality coking coal, low start-up and maintenance costs, low operating temperature compared to long furnaces, and energy saving are some of the advantages of these methods. In the second type of process, natural gas is usually used to separate oxygen from iron oxides.

Best dealing in iron ore in pellet of 2020

These processes are preferred over coal-based processes in areas where natural gas resources are available at a reasonable price. They are also less polluting. Common methods that use a gas regenerator include Midrex and HVL processes. The table below shows the number of countries that have the highest iron production based on direct reduction methods. who are iron ore pellets manufacturers? what are iron ore pellet specifications?

These processes are preferred over coal-based processes in areas where natural gas resources are available at a reasonable price. They are also less polluting. Common methods that use a gas regenerator include Midrex and HVL processes. The table below shows the number of countries that have the highest iron production based on direct reduction methods. who are iron ore pellets manufacturers? what are iron ore pellet specifications?

Today, more than 8 percent of the world’s iron is obtained through the process of direct coal recovery. However, research is ongoing to increase productivity, reduce energy consumption, improve product quality, and improve the overall recovery process.

One of the most popular direct recovery methods used in Mobarakeh Steel Company of Isfahan is Midrex method. The raw materials used in this method are generally oxide pellets. Considering that the pellet production stage is a costly step and on the other hand it leads to environmental pollution, it can be achieved by accessing the iron ore hut with a suitable chemical composition (iron grade above 65% and phosphorus and sulfur minimum). Oxidized pellets alone or in combination were used to charge Midrex furnaces, and in part of the operation, the pelletizing stage was abandoned.

According to studies, India; South Africa, Brazil and Australia are major producers of iron ore in the world with specifications for use in the Midrex method. In Iran, mines with suitable reserves can be found that are able to supply the iron ore lumber required by Mobarakeh Steel Company.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@