Determination of Magnetite iron ore fines price is based on several important factors including total iron purity (total), FeO, percentage of intrusive elements such as sulfur, silica, alumina, and compounds shown in the table below. Of course, factors such as iron ore aggregation are also important. iron ore fines price is determined for the dry product at the temperature specified in the contract.

- Iron ore factory

- Iron ore fines and lumps

- The use of granulated iron ore for blast furnace

- Magnetite iron ore for sale

- Magnetite iron ore price

- Iron ore 60 fe

- Iron ore 55 fe price

- Hematite iron ore price

- Iron ore analysis

- Iron ore price index

- Iron ore price index platts

- Metal bulletin iron ore index

- Dalian iron ore index

- Umetal iron ore price

- Latest iron ore prices

- Iran iron ore fob price

- Price of iron ore concentrate

Iron ore factory

The first step in the process of production of granulated iron ore is the extraction of crude iron ore from the mine. The extraction process is carried out in placer types and openings depending on the conditions and the manner of iron ore accumulation.

Iron ore extracted from the mine is usually of low purity. The number linked to the purity of iron ore extracted from the mine is often below 50%. Therefore, an ore-forming process is needed to increase the purity of iron ore. Of course, the type of process used to increase purity varies. And it depends on the percentage of crude iron ore.

If the crude iron ore extracted from the mine is of low purity, this product will not only be able to increase its purity and usability by the dry process, but needs to be moved to a more processing stage called concentrate. We will study this process at the end of the article.

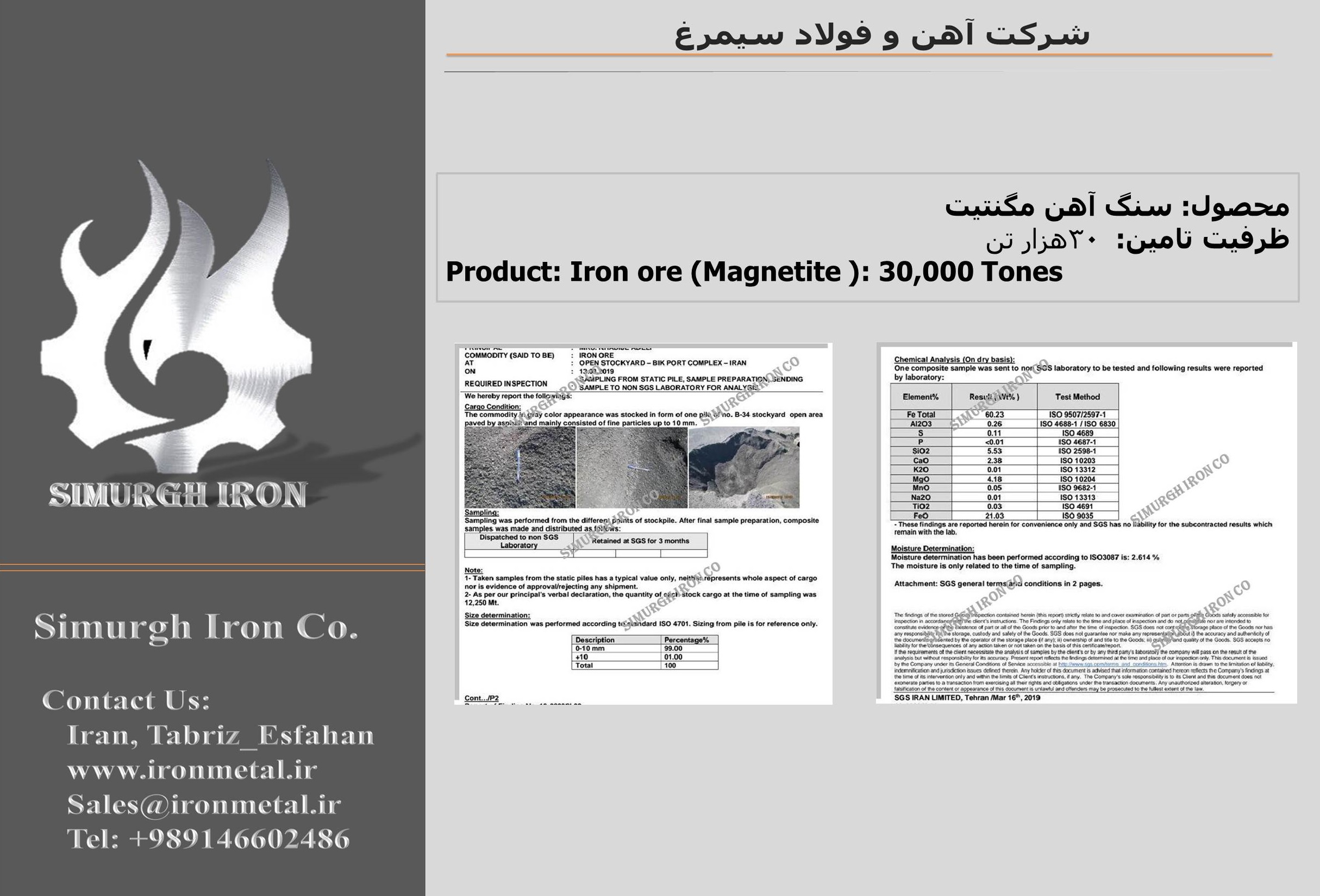

Iron ore analysis report:

| Test Method | Result (Wt%) | Element |

| ISO 9507/2597-1 | 60.23 | Fe Total |

| ISO 4688-1 / ISO 6830 | 0.26 | Al2O3 |

| ISO 4689 | 0.11 | S |

| ISO 4687-1 | <0.01 | P |

| ISO 2598-1 | 5.53 | SiO2 |

| ISO 10203 | 2.38 | CaO |

| ISO 13312 | 0.01 | K2O |

| ISO 10204 | 4.18 | MgO |

| ISO 9682-1 | 0.05 | MnO |

| ISO 13313 | 0.01 | Na2O |

| ISO 4691 | 0.03 | TiO2 |

| ISO 9035 | 21.03 | FeO |

Iron ore fines and lumps

If the crude iron ore extracted from the mine is of relatively high purity, the product will be transferred to the dry processing stage and the product will be used as granulated iron ore.

Mineral dry way that the final product is granulated iron ore, the multi-stage crushing and screening as well as magnetic separation steps aimed at increasing purity, is formed. The resulting product is classified into two categories based on granulated iron ore:

- IRON ORE LUMPS: Granulated iron ore with a grain size of 10 to 30 mm is supplied as iron ore lumps.

- IRON ORE FINES:Granulated iron ore with a grain size of 0 to 10 mm is supplied as iron ore fines.

The use of granulated iron ore for blast furnace

The purity of granulated iron ore after mineralization is often in the range of 57 to 63%. The highest percentage of granulated iron ore produced in the world is used in tall furnaces. Granulated iron ore, due to its high impurities and low grade, is not usable in other types of steel furnaces, ie induction and arc furnaces. Of course, we can say that ninety percent of iron ore, steel chain can be imported in this way. And only about ten percent of it comes into the production chain through other methods, including direct reduction in the form of sponge iron and briquetting iron.

Iron ore, in addition to being classified in terms of iron purity and aggregation, is also classified by type.

Magnetite iron ore for sale

The iron ore extracted from the mine has several types. The differences in the chemical composition of different iron ores are due to their physical properties. One of the important physical properties of iron ore is magnetic properties. Types of iron ore are:

- Magnetite iron ore

- Hematite iron ore

- Zeolite iron ore

- Siderite iron ore

- Limonite iron ore

Of these several types of iron ore, the two types of hematite and magnetite are most commonly used for steelmaking and extraction of iron. Of course, it can be said that over ninety-five percent of iron ore mines are mined in the steel industry for the purpose of iron ore extraction. Of the five types of iron ore, magnetite iron ore has a magnetic property.

Magnetite iron ore price

Iron with Fe3O4 composition is called magnetite iron ore. Magnetite iron ore is black in color and its main characteristic is its magnetic properties.

In the analysis of magnetite iron ore, in addition to the percentage of total Fe (% Fe total), another parameter that is of great interest in the analysis table is the percentage of FeO. The higher the percentage of FeO the magnetite iron ore is placed in the higher the quality and price of granulated iron ore. Sample analysis Two magnetite iron ore samples for 61-60% grade and 56% grade approved by SGS are from depots sold and ready for Simorgh iron and steel industrial and mining complex.

Iron ore 60 fe

Iron ore 55 fe price

| 55.48 | % | Fe |

| 6.81 | % | SiO2 |

| 19.24 | % | FeO |

| 0.60 | % | SO3 |

| <0.05 | % | P2O3 |

| 3.69 | % | CaO |

| 0.07 | % | K2O |

| 6.58 | % | MgO |

| 0.10 | % | Na2O |

| <0.35 | % | Al2O3+ |

| <0.06 | % | TiO2 |

| 2.75 | % | L.O.I |

In global indices, prices of granulated magnetite iron ore for grades 54 to 62 percent are listed.

Hematite iron ore price

Iron with Fe2O3 composition is called hematite iron ore. Hematite iron ore is red in color and is one of the types of iron cations that are widely extracted and exploited for use in the steel industry. Of course, hematite iron ore also has many other uses, such as in the cement industry.

Hematite iron ore analysis also has Fe2O3 content in addition to total Fe (% Fe). Sample of 53% sold hematite iron ore sold by Simorgha Iron and Steel Co. You can check below for an analysis of hematite iron ore. In global indices, hematite iron ore prices, like magnetite, are reported to range from 54 to 62 percent. Of course, for hematite iron ore, a price of 52% purity is mentioned in addition to the above grades. For iron ore hematite the available capacity for purity above 60% is often low.

| Qty | Unit | Element |

| 53.71 | % | T.Fe |

| 0.72 max | % | FeO |

| 75.99 | % | Fe2O3 |

| 1.12 | % | CaO |

| 3.14 | % | MgO |

| 0.53 | % | Al2O3 |

| 0.01 | % | P2O5 |

| 6.99 | % | SiO2 |

| 1.68 | % | MnO |

| 0.004 | % | TiO2 |

| 0.36 | % | Na2O |

| 0.13 | % | K2O |

| 8.97 | % | L.O.I |

Iron ore analysis

Parameters in the analysis of magnetite and hematite iron ore, jointly considered and examined, the percentage of troublesome elements in iron ore. These annoying elements and compounds include:

- Alumina percentage (Al2O3%)

- Silica percentage (% SiO2)

- Sulfur Percentage (% S)

- Phosphorus percentage (% P)

- And …

Iron ore price index

In international business transactions granulated iron ore prices, the global reference indicators are considered. Worldwide iron ore indices that are accepted by most countries in the iron ore trade include the Platts Index (IRON ORE PRICE IN PLATTS) and Metal Bulletin (METAL BULLETIN IRON ORE).

Iron ore price index platts

Studying these indicators reminds us of a few points. The price of iron ore at the Plates site is defined for the standard and specific analysis of the ore. If the gross iron ore traded differs in one of the parameters, the price will change based on this index. For example, with the change in alumina percentage, the price changes by index per cent change of several cents. This applies to all the parameters listed in the analysis to obtain a reasonable price for the traded iron ore based on the global index.

The decrease or increase in the price of granulated iron ore based on the change in the percentage of parameters is also determined in the Platts index. You can find this out by checking the tables below, which are the day’s iron ore price charts on the Platts site.

Metal bulletin iron ore index

Metal Bulletin is an international journal that publishes daily the latest developments in the field of iron ore and other minerals. This publication covers the latest prices of iron ore and related products such as iron ore concentrate, iron pellet price, sponge iron price and most of the steel products traded in the world. The extent of price changes and fluctuations are also considered and the reasons for these changes are analyzed. It can also be considered an international index for day trading in iron ore and other minerals.

Dalian iron ore index

dalian iron ore index is the iron ore daily price index based on the day trades of Chinese ports. That gives an indication of the instant price of iron ore. The latest developments on the Dalian Stock Exchange illustrate the trend of trading in Chinese ports.

Umetal iron ore price

The Umetal Index is known only in China and Iran. The price of granulated iron ore and the price of iron concentrate and the price of iron pellets delivered by Fob Bandar Abbas are determined on the basis of the index itself which is influenced by global price developments. Of course, iron ore exporters in international trade with other countries often make the PLATTS a benchmark in their trade. But in determining the price of iron ore in the mine, the Platts and Umetal index are important for the miner. Some miners consider the iron ore price index in their mine to be Platts and some Umetal.

Prices of iron ore and steel industry stocks from Plates, Metal Bulletin, Dalian Stock Exchange and Umetal are updated daily at the site of Simorgh Iron and Steel Industrial and Mining Complex.

Latest iron ore prices

Here’s a look at the latest developments in iron ore prices for December 2019. The latest trading and review of the World Index of iron ore prices shows positive and incremental changes.

The latest iron ore price change represents a 0.6% daily gain for December 13, 2019. That is a 62% cut of $ 94.6 for the Qingdao Port of China’s CFR Delivery. Iron ore stocks in China’s ports are currently declining. The downward trend in ports is happening for the third consecutive week. At present it has reached 128.08 million tons. Chinese traders have been expecting an improvement in iron ore shipments from Australia and Brazil, but unfortunately, shipments from Australian and Brazilian ports are not favorable.

We are seeing an increase in the price of iron ore at the same time as steelmakers’ margin improvement. Other indices, including the iron ore concentrate price index, and the iron ore pellets price index are also on the rise. The price index growth rate of these products was 3.4% and 5.44%, respectively.

Iran iron ore fob price

(Please note the expiry date prices).

| Shipping C. | W. Change | D. Change | CFR China | FOB BND | Spec | Purity | Products |

| 28$ | 11.3 % | +1 $ | 80.0$ | 52.0$ | 6%Si,2%Al,0.2%P,0.2%S | 60% | Iranian hematite fines |

| 28$ | 13.4 % | 0 | 64.3$ | 38.3$ | 6%Si,2%Al,0.2%P,0.2%S | 55% | Iranian magnetite fines |

| 28$ | 11.0 % | +1 $ | 81.5$ | 53.5$ | 6%Si,2%Al,0.2%P,0.2%S | 61% | Iranian hematite fines |

| 28$ | 11.0 % | +1 $ | 83.7$ | 53.7$ | 6%Si,2%Al,0.2%P,0.2%S | 62% | Iranian hematite fines |

| 28$ | 13.7 % | 0 | 83.8$ | 35.8$ | 6%Si,2%Al,0.2%P,0.2%S | 56% | Iranian hematite fines |

| 28$ | 13 % | 0 | 65.4$ | 37.4$ | 6%Si,2%Al,0.2%P,0.2%S | 57% | Iranian hematite fines |

| 28$ | 12.1 % | 0 | 67.8$ | 39.8$ | 6%Si,2%Al,0.2%P,0.2%S | 58% | Iranian hematite fines |

| 28$ | 10.9 % | +1 $ | 83.1$ | 54.1$ | 6%Si,2%Al,0.2%P,0.2%S | 60% | Iranian magnetite fines |

| 28$ | 11.6 % | 0 | 69.5$ | 41.5$ | 6%Si,2%Al,0.2%P,0.2%S | 59% | Iranian hematite fines |

| 28$ | 10.3 % | +1 $ | 84.6$ | 56.6$ | 6%Si,2%Al,0.2%P,0.2%S | 61% | Iranian magnetite fines |

| 28$ | 10.0% | +1 $ | 86.1$ | 58.1$ | 6%Si,2%Al,0.2%P,0.2%S | 62% | Iranian magnetite fines |

| 28$ | 13.9 % | 0 | 63.3$ | 35.3$ | 6%Si,2%Al,0.2%P,0.2%S | 54% | Iranian magnetite fines |

| 28$ | 12.9 % | 0 | 65.7$ | 37.7 $ | 6%Si,2%Al,0.2%P,0.2%S | 56% | Iranian magnetite fines |

| 28$ | 12.3 % | 0 | 67.4$ | 39.4$ | 6%Si,2%Al,0.2%P,0.2%S | 57% | Iranian magnetite fines |

| 28$ | 11.6 % | 0 | 69.4$ | 41.4 $ | 6%Si,2%Al,0.2%P,0.2%S | 58% | Iranian magnetite fines |

| 28$ | 10.6 % | 0 | 72.8$ | 44.8$ | 6%Si,2%Al,0.2%P,0.2%S | 59% | Iranian magnetite fines |

| 28$ | 6.3 % | 0 | 104.0$ | 76.0$ | 0.1%P, 0.2%S,6%Moisture | 67% | Iranian concentrates |

| 28$ | 6.4 % | 0 | 102.7$ | 74.7$ | 0.1%P, 0.2%S,6%Moisture | 66% | Iranian concentrates |

| 28$ | 6.5 % | 0 | 100.4$ | 72.4$ | 0.1%P, 0.2%S,6%Moisture | 65% | Iranian concentrates |

Price of iron ore concentrate

As mentioned at the beginning of this article, iron ore extracted from the mine is processed into two dry ore units and another wet ore unit, also called a concentrate unit.

As mentioned, low-grade crude iron ore enters the concentrate unit and the higher-grade crude iron ore is transferred to the dry processing unit and production of granulated iron ore.

The concentrate unit has 4 steps in the following order:

- The first stage is the crushing process in which the mineral is transformed into a mineral product with a size below 30 mm.

- The second stage is the process of grinding. At this point, the size of mineral is reduced to 0.5 to one.

- After the grinding process, the mineral grade is then increased. This stage, known as the third stage, is called the stage of purity increase.

- The last step in the concentrate process is the dewatering process.

In the following articles, each of the steps of the concentrate process will be described in more detail.

To find out the latest site inventory and mines of Simurgh Azarbaijan Steel and iron Mining Complex, you can check out the day-to-day material on the company’s site or contact the managers of the complex through the links below.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@