Iron concentrate is the raw material for the production of iron ore. Iron ore is converted to concentrate and then pellets to steel. Iron ore processing is divided into two categories based on the product: production of granulated iron ore and production of iron ore concentrate. Production of granulated iron ore is done dry and without water. Then, using physical separation methods (magnetic method), high-grade iron ore is separated from low-grade tailings. This product, called granulation iron, can not be used in the direct reduction system due to its low grade, but it can be used in blast furnaces. Therefore, iron concentrate price on market is facing price changes due to the rise and fall of currency prices, which you can refer to our site for more information.

What are the uses of iron ore?

Gol Gohar Sirjan Mining Complex is one of the most important suppliers of iron concentrate to the steel industry. Concentrate production in this complex is done by two methods of dry and wet magnetic separation. Phosphorus is an annoying element of iron ore. Knowledge of phosphorus in different granules and in iron ore processing is of great industrial importance.

Due to the importance of this issue, mineralogy and mineralogy studies were performed on the lower iron ore of Gol Gohar mine No. 1 and the following results were obtained. The best concentrate in terms of low phosphorus grade is in the range of 90 to 500 microns. Outside this range the phosphorus content in the concentrate is high; Especially in the dimensional range below 90 microns, phosphorus grade is more visible than other granulation ranges.

The mineralogical reason is the filling of the cavity walls by apatite mineralization and the existence of micro-apatite shortcuts inside magnetite mineralization and in connection with chlorites involved with magnetite mineralization.

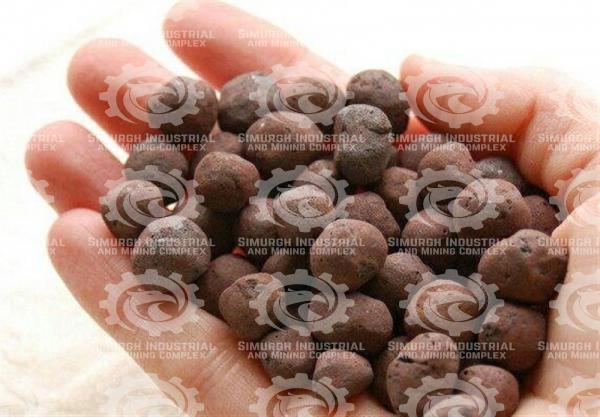

Pellets have the following characteristics: uniform distribution of dimensions, mainly from 9 to 16 mm, high porosity and uniform 25 to 30%, uniform mineral composition in the form of hematite or regenerative hematite compounds, high mechanical strength and uniformity, even mechanical strength, abrasion resistance, Against heat stress in reducing environments and low adhesion.

To convert iron concentrate to pellets, various steps such as the transfer of raw materials, milling, and crushing of raw materials, mixing of raw materials, production of raw pellets, pellet kiln, dusting, cooling water supply, final product transfer, water purification system, compressed air production and Laboratory to be done.

During the production of iron ore pellets, additives and additives such as calcium hydroxide may be added to increase the quality and mechanical metallurgical properties of the pellets. At this stage, the pellets with desirable dimensions and sufficient mechanical strength are produced and sent for transportation to the hardening or baking machine.

iron concentrate price fluctuation

iron concentrate price fluctuation is mostly due to changes in world currency prices, which has caused this product to face price changes and fluctuations.

properties of iron ore Its main use is the production of iron metal. Most of the iron produced is used in the manufacture of steel metal. Steel is also used to make many tools and equipment, such as cars, locomotives, ships, construction beams, furniture, paper clips, bicycles, and thousands of other small and large devices. This metal is in fact the most consumed metal both in terms of consumption and consumption. The main use of this stone is the same 98% for making steel metal and the rest is 2% for other fields as mentioned in the following cases.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@