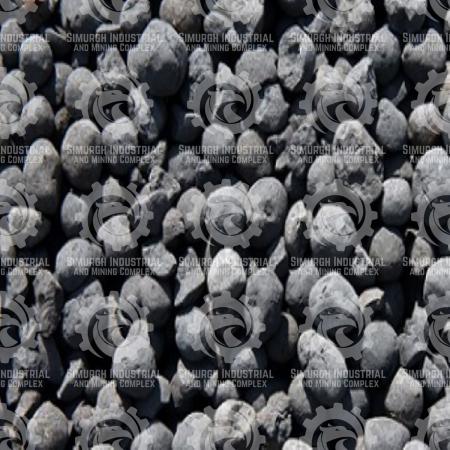

Direct reduction by the PERED method is an Iranian technology that converts oxide granules into metallic iron or sponge iron, which is useful for the production of high-quality steel. The cylindrical reduction furnace uses a highly efficient continuous process flow. For more information direct reduced iron from india visit our website.

Unique Characteristics of direct reduced iron

Iron oxide is filled from the feed tank of the recovery furnace by gravity and from a pipe insulated with sealing gas into the distribution pipes and from there to the recovery furnace. In granular furnaces, it moves downwards with the help of gravity and vibrating feeder and becomes iron metal by direct contact with the reverse flow of reducing gases in the reduction zone. Direct reduction reactions generally occur below the melting point and at about 820 ° C, but in a high furnace, the product is melted due to the high heat capacity of the odor. More energy is required during the steelmaking phase.

Iron oxide is filled from the feed tank of the recovery furnace by gravity and from a pipe insulated with sealing gas into the distribution pipes and from there to the recovery furnace. In granular furnaces, it moves downwards with the help of gravity and vibrating feeder and becomes iron metal by direct contact with the reverse flow of reducing gases in the reduction zone. Direct reduction reactions generally occur below the melting point and at about 820 ° C, but in a high furnace, the product is melted due to the high heat capacity of the odor. More energy is required during the steelmaking phase.

The initial investment and operating costs of sponge iron mills are lower than those of monolithic steel mills and are suitable for developing countries with limited coking coal reserves. Resuscitation is performed by direct resuscitation methods, such as the abdominal cavity of a high furnace, and the resuscitation gas works on iron oxide and reduces it in several stages. The iron oxide feed in this method is in the form of porous granules to pass through the reducing gas.

Reducing gas in direct reduction reactors Before entering the reactor, natural gas (CH4) in the reformers is broken down into CO and H2, and after heating to 1000 ° C, they enter the reduction reactor directly. In direct reduction methods, at least 90% of the iron oxide in the granules is converted to metallic iron, which is the ratio of the total iron formed to the total iron content in the granules.Most iron ores are mined by surface mining. There are some underground mines, but where possible, surface mining is preferred because it is cheaper. On average, the ore grade is about 60 to 65%, concentrating and increasing the ore grade depending on its initial grade, which includes crushing, milling and physical and magnetic methods . For more information on Direct Reduced Iron Supply, visit our website.

Exporting direct reduced iron from india

Exporting direct reduced iron from india is possible by our company and our company distributes this product at a good price and has made even other countries buy this product, so you can For more information about Direct reduced iron price, visit our site.

Exporting direct reduced iron from india is possible by our company and our company distributes this product at a good price and has made even other countries buy this product, so you can For more information about Direct reduced iron price, visit our site.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@