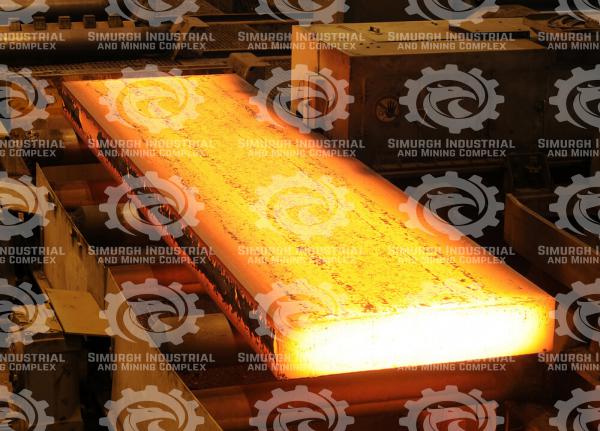

steel ingots types are industrial products that must be manufactured from sheets with certain technical and mechanical characteristics. Technical specifications these types of sheets which include all the physical and chemical characteristics required in the manufacture and manufacture should be provided by sheet manufacturing factories.

What is steel ingot?

The thickness of the steel ingot price core of the roofs of the steel deck is determined according to the structural conditions. All stages of production in the thickness of the sheet, the impact of the stronger. hence, quality control, production sheets, the Raw of particular importance is of the same order in the different countries of the world standards of quality control roofing sheet there.

The thickness of the steel ingot price core of the roofs of the steel deck is determined according to the structural conditions. All stages of production in the thickness of the sheet, the impact of the stronger. hence, quality control, production sheets, the Raw of particular importance is of the same order in the different countries of the world standards of quality control roofing sheet there.

Roof sheets are cold rolled type and are set in different standards of certain tolerances for sheets with certain thicknesses. The minimum thickness of the roofing sheets in addition to the structural profile depends on the profile of the sheets covering.

Corrosion control is of great importance due to its impact on the strength and operation of steel ingot minecraft. Hence the metal core of the roof must be protected by appropriate coating. One of the most effective methods of protecting the sheet is the use of metal coatings on the raw sheet. For example, combined alloys of iron and zinc can create appropriate coatings for the roof, which controls corrosion in various climatic conditions. In addition alloys, in … protective cover for sheet raw material are expected to be in. there in the alloy causes corrosion on the cutting scratch on minimized. This type of protection occurs when two different types of metal that are in contact with water and oxygen are in contact. For example, the type coating (z275) G90 performs this type of protection for sheets up to a thickness of one millimeter. Further explanations on cathode protection are found in the standards of engineering materials.

Purchase Different steel ingots types

Zinc – aluminum alloy-type coatings have similar functions but this type of coating is not suggested for proximity with fresh concrete similar to what occurs in compound deck slab ceilings. The metal coatings used for the roofs of the steel deck should be implemented in a hot deep galvanized way on the sheets. The main cover used on the roofs of the steel deck type (ZF075)ta25 with the composition of iron and zinc. Of course, heavier coatings may be required for dire weather conditions. Metal coatings may be sensitive to stains on them due to environmental conditions, this is especially sensitive when there is some moisture between the roof sheets in a bundle for a long time. The environmental conditions may be colour alloy, iron, and zinc in the cover sheet to dark gray change that after a while the color to reddish brown, may also change the color of the finds. The surface of the zinc coating may turn into white powder under rust condition. Often, such rust prevents the metal from protecting the core and is reusable by staining. To prevent this rust should pay attention to the conditions of loading and maintaining the sheets.

Zinc – aluminum alloy-type coatings have similar functions but this type of coating is not suggested for proximity with fresh concrete similar to what occurs in compound deck slab ceilings. The metal coatings used for the roofs of the steel deck should be implemented in a hot deep galvanized way on the sheets. The main cover used on the roofs of the steel deck type (ZF075)ta25 with the composition of iron and zinc. Of course, heavier coatings may be required for dire weather conditions. Metal coatings may be sensitive to stains on them due to environmental conditions, this is especially sensitive when there is some moisture between the roof sheets in a bundle for a long time. The environmental conditions may be colour alloy, iron, and zinc in the cover sheet to dark gray change that after a while the color to reddish brown, may also change the color of the finds. The surface of the zinc coating may turn into white powder under rust condition. Often, such rust prevents the metal from protecting the core and is reusable by staining. To prevent this rust should pay attention to the conditions of loading and maintaining the sheets.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@