Slab is a linear and semi-finished product produced by the ingot rolling process or continuous casting process. The cross section of the slab is not square, unlike ingots or ingots, and is rectangular in shape and is used in the heavy machinery industry as well as a raw material for making flat rolling products such as coils and hot rolled plates. Usually the thickness of the slab ranges from 200 to 250 mm, its width from 650 to a maximum of 2000 mm, and its length from 4 to 12 meters. Slabs have a limited market and around 20 million tons of slabs are produced annually in the world and placed in the sales cycle. For more information on premium steel slab 2021 market size, visit our site.

Unique Characteristics of Premium steel slab

Plate or plate production begins with the extraction of iron ore from mines. Stone extracted from mines is not of high purity and needs to be renewed. Restoration of iron ore is done in two ways: Direct reduction (by continuous casting) Indirect resuscitation (by hot rolling) Plate production by direct reduction (Direct reduction) In this method, reduction is made by using natural gas fuel in the furnace. The output of the direct reduction furnace is sponge iron, which is often used as briquette. Scrap iron is poured into an electric arc furnace and then coke, lime, bentonite, etc.

Plate or plate production begins with the extraction of iron ore from mines. Stone extracted from mines is not of high purity and needs to be renewed. Restoration of iron ore is done in two ways: Direct reduction (by continuous casting) Indirect resuscitation (by hot rolling) Plate production by direct reduction (Direct reduction) In this method, reduction is made by using natural gas fuel in the furnace. The output of the direct reduction furnace is sponge iron, which is often used as briquette. Scrap iron is poured into an electric arc furnace and then coke, lime, bentonite, etc.

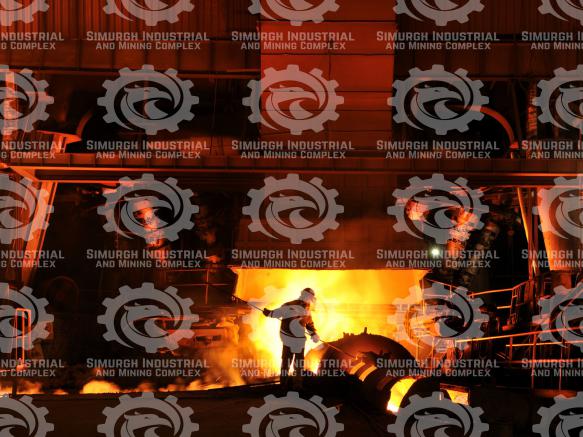

Sponge briquette iron with slag materials is added to the furnace from above. The furnace is charged by the heat generated by electric arcs. The chemical composition of the melt is checked again to achieve the desired state. Finally, after the foreign materials are separated, the molten material is taken to the casting unit by means of trays carrying the molten material. The molten material is poured into a container called tundish, then the copper is placed in a water mold, placed on a roller and cooled by spraying water. A traditional method of producing plates is the blast furnace method, which is carried out by indirect reduction.

This method is a practical method due to the high coal resources in Iran. First, iron ore enters the blast furnace with lime and crude iron, and crude iron is obtained by removing carbon and adding oxygen to crude steel. In the continuous casting unit, the molten material is poured into the mold, the product is separated from the mold and the plate is cooled by spraying cold water and turned into frozen ingots. Finally, desired plate lengths can be achieved with different cuts. The most important application of floors is to obtain various types of steel sheets.

In fact, plates, ingots, ingots are not widely used. To produce any type of steel sheet, the sheet must first be heated to a certain temperature. The product that comes out after the plate is rolled is black plate or hot plate. The same hot sheet produced under operation, other oil plates, galvanized plates, acid washing plates, etc. It happens. For more information on steel slab design visit our site.

Market size of Premium steel slab

Market size of Premium steel slab is growing well because it has a good price and many customers go to this product and buy this product. Therefore, you can visit our site for more information about stainless steel slab.

Market size of Premium steel slab is growing well because it has a good price and many customers go to this product and buy this product. Therefore, you can visit our site for more information about stainless steel slab.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@