In the central steel coil, the torque is inserted into the core or mandrel, which is wrapped around the steel plate. This can be done in the presence of a roller that pulls the sheet to the mandrel and presses it. In coil dispensing, Central without the presence of the roller pressure, etc.

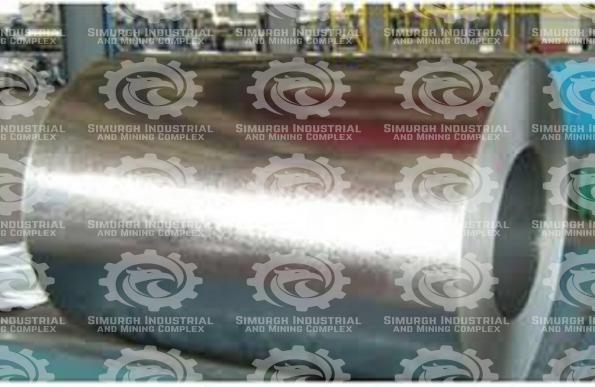

What is stainless steel coil?

One of the common methods and economic for storage and transport steel coils for sale, such as steel sheet, etc. aluminum, steel, plastic, paper, polymers, etc. magnetic tape, and the … in different factories produced wrap it and bring it in to The Shape of the coil or the coil is.

One of the common methods and economic for storage and transport steel coils for sale, such as steel sheet, etc. aluminum, steel, plastic, paper, polymers, etc. magnetic tape, and the … in different factories produced wrap it and bring it in to The Shape of the coil or the coil is.

locked inside the weather is getting between the layers is one of the things that need to be considered, because it can cause bad quality coils crafted. The use of the compressive roller can reduce the effect of this factor, because the compression that this roller enters when the coil is screwed out the air between the layers. Many polymers and metals such as steel and aluminum are screwed into the central method. For the central screw reel may be considered different profiles of traction. Its two major types are constant traction mode or constant torque.

This action, which is called a bolt coil, is performed by a device called tension rails. Due to the extensiveness of this process in various industries, and the necessity of a scientific survey to determine its exact parameters involved in it to produce with optimal quality and minimal defects is required. Continuous strips of paper, polymer and metals such as steel and aluminum and other materials with low thickness are seen in various factories. These materials are flat and flexible sheets that undergo a certain speed and elasticity during their production process.

Export business of steel coil

A remarkable initial method for rapid production of high-speed and inexpensive metal pipes was patented by James Russell in 1824. In his method, the steel coil price were created by adhering to the opposite edges of the iron flat bar. The metal is first heated until it is flexible. Using a hammer, the edges are joined and welded together. The pipe passes through the groove and the Rolling Mill reaches the final production stage.

A remarkable initial method for rapid production of high-speed and inexpensive metal pipes was patented by James Russell in 1824. In his method, the steel coil price were created by adhering to the opposite edges of the iron flat bar. The metal is first heated until it is flexible. Using a hammer, the edges are joined and welded together. The pipe passes through the groove and the Rolling Mill reaches the final production stage.

The Russell method was not used for a long time because in the following year, Whitehouse developed a better method for making metal pipes. This process, which is called butt welding process, is the foundation of the current methods of pipe making. In his method, thin sheets of iron are heated and drawn through a cone-shaped openings. By passing the metal from the open edge, its edges are twisted and The Shape of the pipe is created. The two ends are welded together to make the pipe finish.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@