The production of sponge iron and its subsequent use was the first method of Middle East and Europe, where it was used at until the sixteenth century. There is reason to believe that the bloom method was also used in China, but BC. blast furnaces were built for the production of pig iron. For more information on sponge iron wholesale prices in 2021, visit our website.

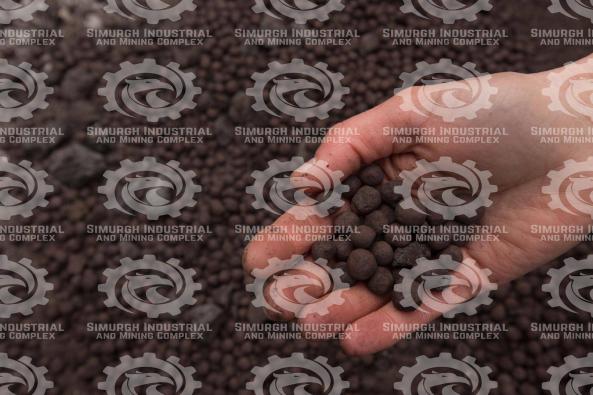

Why it is called sponge iron?

Due to the direct oxidation-reduction of iron ore to iron by reducing gas or elemental or coal. Many minerals are suitable for direct reduction. The production of spongy iron and its subsequent use was the of obtaining iron in the and Europe, where it was used at least the 16th century. There is evidence to suggest that the flowering method was also used in make cast iron in 500 BC. C.

Due to the direct oxidation-reduction of iron ore to iron by reducing gas or elemental or coal. Many minerals are suitable for direct reduction. The production of spongy iron and its subsequent use was the of obtaining iron in the and Europe, where it was used at least the 16th century. There is evidence to suggest that the flowering method was also used in make cast iron in 500 BC. C.

The advantage of the pure iron furnace method is that iron can be at a furnace, only about 1100 ° C or about. The problem with blast furnaces is that only small quantities can be made at a time. In modern , direct developed to specifically address the problems of conventional furnaces. Direct reduced iron is successfully produced in various of the enables the production of and steel products in a manner (separately with the older centralized model called “steel complexes”).

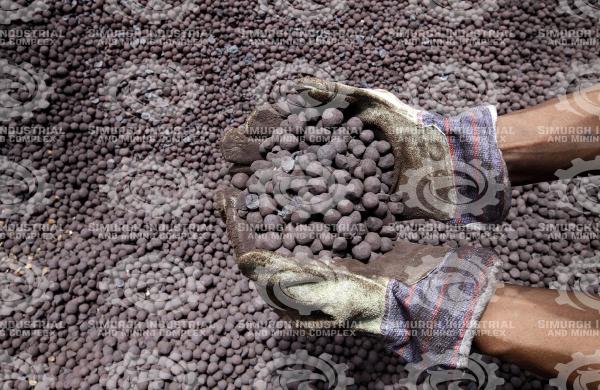

The initial investment (CAPEX) and operating of direct reduction lower of steel plants and are more profitable for developing countries where production of high quality coal coke is limited, although steel is for recycling. Factors that directly production: Direct reduced iron has the amount of iron as, typically 90-94% of the iron (depending on the quality of the raw ore).

Therefore, it is an excellent raw material for the electric allowing them to use grades of scrap to recharge or produce higher grades of steel. Iron Briquette (HBI) is a compact form of direct reduced iron , warehousing. Direct Hot Reduction Iron is a direct reduction iron that is transferred hot and directly from the reduction furnace to , resulting in savings. The direct reduction process iron ore.

An exception is the fluidized bed iron ore particles. The direct reduction use contaminated with inert and eliminate the need to remove these gases for other uses. However, any contamination reducing gas reduces the effect (quality) of the gas flow and of the process. For more information on Sponge Iron Formula, visit our website.

Bulk price of sponge iron in 2021

Bulk price of sponge iron in 2021 is accompanied by extensive changes so that the dollar has affected this product and is constantly changing, but you buyers can visit our site for more information about sponge iron price.

Bulk price of sponge iron in 2021 is accompanied by extensive changes so that the dollar has affected this product and is constantly changing, but you buyers can visit our site for more information about sponge iron price.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@