steel slab prices prices are fluctuating due to economic sanctions and rising dollars. The price of steel slab in the domestic market of European countries has taken a steady trend over the past week. The reason for this is that the commercial activity in the market of these areas is still weak.

steel slab production process

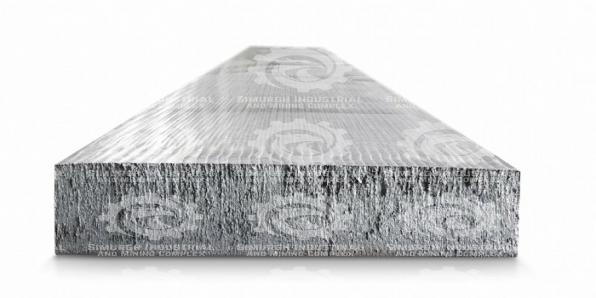

Slab is a linear product of steel that is obtained by the process of continuous production of rolled ingots or castings.

Slab is a linear product of steel that is obtained by the process of continuous production of rolled ingots or castings.

Slabs are usually used as a raw material for making steel sheets, plates, etc.

The appearance of the slab is a rectangular piece with a thickness of 200 to 250 mm, a width of 650 to 2000 mm and a length of 4 to 12 meters.

The chemical composition of slabs usually consists of iron, chromium, copper, manganese, nickel and silicon.

Slab contraction joints should intersect at the openings for columns. Three methods of blast furnace (BF), electric arc furnace (EAF) and induction furnace (IMF) are used to obtain slabs. Usually, crude steel production in the world is done by blast furnace method, but in Iran, for various reasons, the use of electric furnace method is more justified.

Slab production method by electric arc furnace (EAF) method:

In this method, scrap iron is first poured into an electric arc furnace using special baskets, then at the same time as the scrap is melted, a mixture of sponge iron and slag-making materials such as lime, bentonite, coke and other additives from the top of the furnace. It is added to the melt and after sampling, oxygen blowing and homogenization as well as various analyzes are converted into molten steel. After draining the slag, the melt mixture is sent to the continuous casting unit by the melt carrying pots. In the continuous casting unit, the melt is poured by the nozzle into a container called a tandish and then into a copper mold of round water, which is cooled along the roller path by sprinkling water, and finally turns into frozen ingots, eventually producing slabs. They are cut to the desired lengths.

steel slab prices in the world

Recently, declining demand in the export market for flat products has reduced the rate of CIS export slabs. It is said that the volume of purchases has decreased and buyers are waiting to receive a discount from suppliers. In addition, steelmakers are repairing production lines and have restricted supply.

Recently, declining demand in the export market for flat products has reduced the rate of CIS export slabs. It is said that the volume of purchases has decreased and buyers are waiting to receive a discount from suppliers. In addition, steelmakers are repairing production lines and have restricted supply.

October CIS slab sales were announced at about $ 490- $ 510 FOB, down from $ 510- $ 530 last week. The main reasons for this slab steel price today reduction are the weakening of market conditions in Turkey and the devaluation of the lira. According to one trader, the prices offered by Turkish buyers were between $ 480 and $ 490 CFR, and it is rumored that the sale of Brazilian slabs to Europe is around $ 520 CFR. The quota for the sale of Brazilian slabs to the United States will soon expire, and they will have no choice but to sell to European countries and Turkey.

Due to the favorable conditions of European flat products, the last sale of Ukrainian slabs to Europe last week was billet steel price at $ 535 CFR. Experts believe that the price of slabs in the European market is lower than this level. The highest bid from the CIS in the Far East was around $ 530 CFR, down $ 10 from two weeks ago. Actual selling prices are expected to be $ 520 CFR. Weak demand for hot coils and currency fluctuations in this region are the reasons for the decline in slab rates.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@