dri sponge iron price in Iran Similar to all products on the upstream of steel Also other ironware is up to date and it can fluctuate at any moment. This fluctuation is usually influenced by the foreign market, or for reasons such as closure or the so-called “shut down” of one of the major mills of the producer or scrap metal scrap in the meantime.

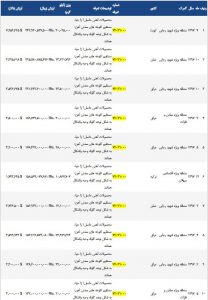

- Sponge iron price 2019

- Iron ore prices

- Sponge iron production in Iran

- Sponge iron process

- DRI midrex process

- Persian reduction iron ore dri

- Iran Sponge Iron Exports

- Prohibition of Sponge Iron Exports

- Controversy on Sponge Iron Exports

- Direct reduced iron prices

- Jumbo Bag Packaging on Sponge Iron Export

- Iron briquettes price

- Sponge iron briquette

- Sponge iron cold briquettes

- DRI HBI price

- Briquettes sponge iron fines

- Briquettes iron manufacturing plant

- Price briquetted iron

- Scrap iron prices

Sometimes this fluctuation may even reach $ 20 a tonne for sponge iron price per ton (sponge iron price today) over a period of one to two weeks. And since the purchase of sponge iron for domestic or export factories is in high tonnage and regular scheduling cycles, the precision of closure of such contracts and the use of official trade experts is felt.

Sponge iron price 2019

As you know, sponge iron production in Iran is very high. According to the volume of annual production of sponge iron, Iran is ranked the country with India as the largest producer of sponge iron. The annual production of sponge iron in our country is still rising. Iran is now a major pillar in the production and export of sponge iron in the world.

Due to the export of high-volume sponge iron from Iran, the world market conditions and fluctuations affect the price of sponge iron for the delivery of fob ports in our country. Due to the export of high-volume sponge iron from Iran, the market conditions and fluctuations affect the price of sponge iron prices for the delivery of fob ports in our country. As you know, the latest changes in the price of upstream steel products have been uptrend. The price of sponge iron is no different from this.

Iron ore prices

Of course, at the beginning of June 2019, demand reduction has led to a downward trend in prices. Changes in the price of iron ore in the world have been rising since the beginning of 2019. But in the last few days (now June 2, 2019), we see a relative decline in iron ore prices. The reason for this is the decline in demand for purchase. Most steel factories have lowered their production this month, and they are repairing and cleaning the equipment. Due to the low volume of demand, the purchase iron ore prices decreases. Therefore, the price trend is a downward slope.

Sponge iron production in Iran

The latest reported figures for Iran’s sponge iron production, reported by the World Steel World Association, are about 2.395 million tonnes, showing an average monthly growth of + 7.6% for the month of April 2019. The average increase in production in the first five months of 2019 is estimated at + 17.7%.

Sponge iron process

In Iran, sponge iron is produced mainly in two ways:

- Perred (Persian Reduction)

- Midrex

DRI midrex process

The Midrex process for the production of sponge iron, seen in the video placed in the first part of the paper.

Persian reduction iron ore dri

The PERRED process, abbreviated to Persian Reduction, is native technology designed by Iranian experts and successfully exploited in the industrial dimension. Currently, a number of factories producing sponge iron in our country, using this technology, have started to produce major sponge iron and are successfully supplying the product.

Among the factories that process and produce sponge iron with Persian Reduction technology, we can mention Miyaneh Steel Co. as well as Ghadir Nayriz Steel Company. As you know, the product of Miyaneh Steel Co is one of the best kinds of sponge iron produced in our country. In addition to extensive use in domestic steel mills, its export to various countries is being carried out by exporters of iron and steel industry.

Iran Sponge Iron Exports

Exports of Iran sponge iron with HS code 72031000 to various countries such as Kuwait, Oman, Iraq, Turkey, Malaysia, Indonesia, India, UAE, Syria, China, Pakistan and Georgia. Exports of this product in the form of sponge iron pellets in bulk and jumbo, are also briquetted. Iran’s Sponge Iron Exports are developing in this country by increasing production of this product.

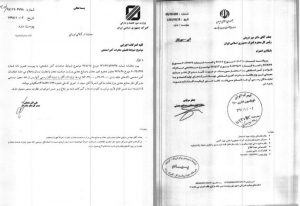

Prohibition of Sponge Iron Exports

As we know, the number of steelmaking units equipped with induction furnaces and arc furnaces in Iran, due to a more convenient gas supply, is large and expanding. The raw material and feed of this kind of furnace is sponge iron with scrap. Therefore, given the fact that steel units are active in our country, supplying the needs of domestic factories should be prioritized.

Therefore, at some time periods, the Ministry of Industry, Mining and Commerce, with the aim of controlling and supplying the domestic market, imposes restrictions on the export of sponge iron. These rules are updated and changed as market conditions change, which is communicated to the customs of the country through the Ministry of Industry, Mines and Trade. (In 1397, it was implemented by the Ministry of Education.)

Controversy on Sponge Iron Exports

Fortunately, exports of sponge iron are currently not forbidden. But it is conditional. In this case, the export of this product can only be done by the sponge iron producer or its legal representative.

Direct reduced iron prices

Sponge iron is one of the upstream steel products that is being offered on the stock exchange. Sometimes, we see the difference in prices announced in the stock market, with the involvement of the Steel Association and the Ministry of Industry, Mining and Commerce, with the aim of controlling the market for the supply of sponge iron, on the price of sponge iron on the stock exchange. Therefore, its price varies with the free market rate. Now that we are on June 8, 2019, the price of sponge iron on the stock exchange is close to the price of sponge iron on the free market.

Jumbo Bag Packaging on Sponge Iron Export

Sponge iron is a porous bullet with a size of 6-25 mm which is highly sensitive to the oxidation process due to porosity. If this product is exposed to heat and moisture, oxidation process is carried out more quickly. So there is even the possibility of ignition. In the face of oxidation and ignition, sponge iron, unfortunately, carbon, this product is completely sucking, and so-called sponge iron, and it gets inside the yellow. This sponge iron is not usable in electric arc furnaces, and especially induction furnaces, which are more sensitive to arc furnaces.

The sensitivity of sponge iron makes it advisable for our customers to buy this product in the appropriate package called Jumbo Bag, which is manufactured in a size of one ton, as a sponge iron seller and exporter. The use of Jumbo Bag is not economically justified if there is domestic transportation and the distance is short, but the use of Jumbo Bag is strongly recommended for international export and international shipping, especially if it is shipped and the cargo is exposed to moisture.

Iron briquettes price

Of course, iron briquettes do not have the dangers mentioned in the previous section. Sponge iron briquettes are the product of briquettes and compressed iron sponge iron under the briquetting process. The briquetting process in three types of cold briquettes is also divided into hot briquette production and, of course, the production of briquettes sponge iron fines.

In the following, we give a brief explanation of the three types of iron briquettes.

Sponge iron briquette

Sponge iron cold briquettes

The input of the briquetting machine in the production of this kind of briquette has ambient temperature. Therefore, this product is known as cold briquettes.

DRI HBI price

The input of the briquetting machine in the production of hot briquetted iron is about 650 ° C. In fact, the charging input of the briquetting machine is in the production of hot briquetted iron at a temperature of 650 ° C. This temperature is exactly equal to the temperature of the sponge iron at the exit stage of the direct reduction unit.

Briquettes sponge iron fines

Briquettes sponge iron fines are made from broken and so-called sponge iron fines, which are separated during the product transfer from the direct reduction unit to the steel line from the main product. In the production of Briquettes sponge iron fines, silicate glue is also used for agglomerating with sponge iron fines. The grade and analysis of sponge iron fines used to produce Briquettes iron, determines the final quality of Briquettes sponge iron.

Fortunately, the possibility of briquetting sponge iron and supply in this way is a good solution to the problem of transportation and storage. So there is no longer an obligation to use Jumbo Bag to export it. Unless the buyer declares the use of these bags to us.

Briquettes iron manufacturing plant

At present, some of the factories producing iron briquettes that produce cold briquettes in hot and cold fashion are working in our country. Iran is one of the few countries in the world and the Middle East that has achieved the technology of generating briquettes, and it is already exporting extensively. More than 90% of our bronze iron sponge iron products are exported to our country. Countries such as Syria, Oman and … are the main buyers of hot iron bronze sponge iron from our country.

Iron cold briquettes are also produced by a number of factories in a massive volume and sold in addition to supply in the export sector. Fortunately, the use of cold sponge iron briquettes is increasing among the domestic steel mills, even small units and factories. The use of sponge iron briquettes has many advantages for a steel production unit, provided that it receives sufficient training from the supplier of this product and acquires a full understanding of the technology and method of use of the product.

Price briquetted iron

Price briquetted iron is often higher due to the secondary processing process used to produce this product on sponge iron. But often because of the advantages it has in sponge iron, both in terms of transportation and warehousing of the product or the advantages that are used in the melting unit, it is welcomed and the choice of buyers who have steel factories equipped with electric arc furnaces. One of the main advantages of using sponge iron briquettes in comparison to sponge iron in the melting process is the possibility of using it with a higher percentage of the iron scrap. This provides a significant cost benefit to the steelmaking plant. We can even say that the higher the price of the product itself, which the steel mill at the purchasing stage has to accept and pay.

As you know, the price of scrap iron is high. The use of one hundred percent iron scrap for melting is not economical. For this reason, sponge iron is used in conjunction with it for melting. Now, if we can increase this ratio of sponge iron or iron briquetted to scrap, we have been able to save on the inputs of our steel mill.

Scrap iron prices

The price of iron scrap increased aligned with the price of its upstream steel products, which include iron ore, iron ore concentrate, iron pellet, sponge iron and iron briquettes, and, of course, due to rising steel prices in the global market. As we know, access to iron scrap is somewhat difficult given the limited supply. Its price is also high. Therefore, deficiency compensation and cost can be done using upstream products. Iron ore and iron ore pellets can be used in long oven furnaces and converters, but not suitable for induction furnaces and arc furnaces. A product that is intermediates between mining and steel making and it can be used for these two kinds of furnaces, namely electric arc furnace and induction furnace, is a sponge iron and iron briquettes, which is described in detail in the above article with detailed introduction and market analysis.

Simorgh Iron and Steel Co., supplier and exporter of upstream products such as granulated iron ore, iron concentrates, iron pellets, sponge iron and iron briquettes are also steel products such as billet, billet, bloom and slab. Also, from the final products of steel, the supplier of steel fittings in different sizes in four types of rebar a1, rebar type a2, a3 is also a type A4 rebar. For more information and to receive inventory and order registration, you can contact the company through the following communication paths.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@