Iron ore prices chart

Important factors in determining the price per ton of iron ore concentrate in the sale of export iron concentrate As mentioned in the beginning of the text, there are two cases:1) Iron ore concentrate price per ton in the world

The global fluctuation of the global iron ore prices will subsequently affect the price quotations in the markets of the exporting countries. The Chinese market in the international arena has the greatest impact on the price of iron ore daily prices (generally upstream products or even middle and final products of the steel industry). Because it is the largest importer of iron ore and the major exporters and consumers of steel products in the world. Any change in the iron ore inventory at chinese ports or the demand for the consumer market for steel will subsequently affect on global iron ore prices. The main destination for Iranian iron ore exports is also the export destination of iron concentrate, China. Dollar prices for delivering Iranian ports to iron ore are based on the global rates of these products. The global fluctuation will cause a price fluctuation in Iranian ports. To get the price of iron ore, pellet and iron ore concentrate, please refer to the iron ore price list page.2) Shipping cost from Iranian ports to destination country

The costs and conditions for shipping and shipment from Iran are affected by the political conditions and existing sanctions. Currently, the bulk shipping charge on bulk ships ranging from Bandar Abbas to mainland ports in China ranges from $ 29 to $ 50 per container. The fluctuation in the price of the shipping costs or other parts of the logistics process also has an impact on the final price, of course, of delivery to the cfr. Of course, effective factors are not just the two. There are many other parameters that we can point out to factors such as the existence of unilateral sanctions against Iran and, unfortunately, the lack of cooperation of international shipping companies with our country. This has affected exporters’ bid prices and their success in providing affordable prices to their customers. An example in this regard can provide us with a better understanding. We will mention these two issues in more detail in the following headings.Export of iron ore concentrate

The possibility of cooperating with large international shipping companies to carry raw steel raw materials from our ports to other parts of the world is necessary to successfully export iron ore concentrate and other steel products. Fortunately, our exporters have been able to deliver products agreed with their customers in spite of some of the problems that will be mentioned later. The problems are the same. Unfortunately, strict sanctions against Iran and control by the US government to prevent global circumvention of the sanctions have caused international ships to miss out on Iranian ports. Until now, ships shut off the gps by logging in to Iran’s commercial ports and exchanged their dealings with Iran, but recently, unfortunately, there is no such thing as a US-Gulf fleet. This has led to a decline in the relative price of iron ore concentrate in the global market. Because exporters can not communicate effectively with their buyers.World price iron ore concentrate

The latest global changes on iron ore concentrate price per ton show an increase in the price index of this product in Chinese ports. (February 2, 2019). The price increase per tonne of iron ore concentrate in China was about 9.4% and reached about 103 dollars per tonne. As we mentioned earlier, the main reasons for stimulating the market and the upward trend in prices are supply shocks from Vale, Brazil. The latest price changes are posted on the site of the World News website. Please refer to this page. More recently (update on May 20, 2019) the restrictions on the supply of BHP and Rio Tinto companies along with an increase in demand for the purchase of China has exacerbated the fluctuation of the price of iron ore and iron ore concentrates.The price of iron ore concentrate 67% Fe

The price of iron ore concentrate 66 Fe percent delivery to the fob ports of the countries exporting this product for February 2, 2019 can be viewed and read below. The daily rate on the price page of iron concentrate is set to date.- Iron ore concentrate in Iran: The price for 66 percent is about $ 71.3 per ton.

- In Russia, iron ore concentrate is $ 83.0 per tonne.

- Iron ore concentrate Price per ton Ukraine’s exports are $ 78.8 per ton.

- The price of American Iron Concentrate is $ 77.0 per day.

- The price of iron concentrate in Canada is $ 84.2.

Zanjan iron ore concentrate

You can see Zanjan Iron Ore Concentrate Analysis below. Fortunately, the percentage of iron concentrate is more than 67%. Percent sulfur, phosphorus is estimated to be below 0.05 and 0.08, respectively. The percentage of impurities such as silica and alumina in total are shown in below analysis 4.2. Humidity is less than 9%. FeO less than 28%. You can contact us at the bottom of this article to contact us for the product information at the end of this article.| >=67 | % | Fe |

| >=28 | % | FeO |

| <0.05 | % | S |

| <0.08 | % | P |

| <1 | % | CaO |

| <4.2 | % | Al2O3+SiO2 |

| <9 | % | Moisture |

| <70 | Micron | K80 |

| >1600 | Cm2/gr | Blain |

Iron ore concentrate vs fines

Sales of iron concentrate with a basic base grade of 68.14%, 65% reject, are made by Simurgh Iron and Steel Company in a tonnage of 200,000 tons delivered to Bandar Abbas. Also with a purity of 66% reject 65%, is offered in a monthly tonnage of 30,000 tons. If you want to check the analysis and impurities of any product, you can contact the sales department of the company. In the following section, you can see iron ore concentrate with a purity of 66% iron percentile 65%. Both the chemical characteristics of the iron ore concentrate and the physical characteristics are completely included in this section.| Fe 66.00% Min. Al2O3 0.75% Max. SiO2 5% Max. Sulphur 0.05% Max. Phosphorous 0.03% Max. Free moisture (loss at 105 degrees centigrade) 10% max. |

| Size More than 0.07 mm for at least 70% of cargo. |

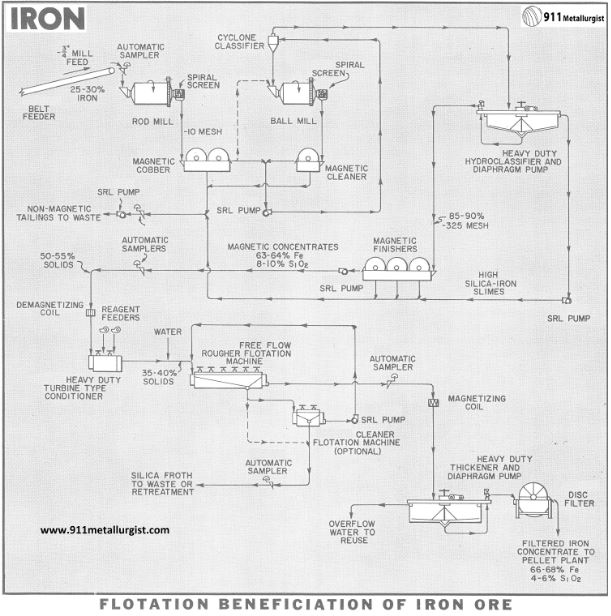

Iron ore concentrate production process

The iron ore after the extraction and removal process from the mine is necessary to remove impurities such as phosphorus, sulfur, alumina, silica, etc., as well as increasing the purity and grade of iron ore. The processing stage is based on the product obtained from the processing into two groups of production of fines and lumps iron ore and the production of iron concentrate.1) Production of granulated iron ore (fines iron ore and lumps iron ore)

The process of producing iron-bound iron is a dry process. The raw material and in fact the feed used to produce iron ore, iron ore is in the range of 50%. The resulting high iron ore grade is about 60-62%, which is in two or three classes in size. The grinding process is carried out in the process of producing iron ore graded in three steps, and it is shaken. Then, the process of increasing purity is carried out mainly by magnetic methods, and the product of the particle is separated from the waste gypsum. The most important and only used iron ore granulated, the furnace is long. Because this product is not usable for direct reduction. Of course, in the process of processing and production of granulated iron ore, the precedence of the abovementioned steps can be completely dependent on the feed of each plant and the unit of mineralization.2) Production of Iron Ore Concentrate (Concentration process)

In cases where the purity of the ore deposit and the percentage of impurities are more than acceptable, it is necessary to perform more complex processes on the product in order to process it. Processes that are collectively referred to as concentrating processes include grinding, milling, purification and final dewatering processes. The transportation and water supply units for the concentrating plant operate in the factory units. The process of concentrating is discussed in more detail below. We introduce the process of concentrating in the five steps we fully describe below.- In the first stage, the feed unit in the crushing plant giratory to dimensions below 20-25 cm, finds crushing. Of course, at this stage, the input of iron ore in the feed with a small size or equal to the output product is prevented. Until these dimensions enter the crushed stone and do not diminish the dimensions.

- The second step is to transfer the output of the first stage with the conveyor to the second stage of grinding. This step is governed by mineral characteristics. It may contain two dry crushing steps. The material and output of this stage stone is about 30 mm in size. Of course, the crushing process is carried out in several steps with the aim of controlling the granulation.

- The third step is the milling process. The feed (mineral) with dimensions below 30 mm enters the milling plant. This step is wet. The product of this process is a mineral material in the range of 0.5-1 mm. The resulting product is then converted to a smaller size with ball mills. This step is also done wet. In this section, gradient control is performed by hydrocylins. Floating material in water (slurry composition = slurry) is guided by a pump.

- The mineral has been thinned and thinned after the milling process. At this stage, the product enters the process of purification with the aim of separating waste and impurities from the slurry. For this slurry derived from the previous process, a magnetic separation with magnetic separators of the type of drum is guided. This is done through pumping. By slurry passing through the drums, iron particles are absorbed by the drums and the waste is removed from the debris.

- The final stage is the de-watering process. The purified iron ore has a moisture content that is too high. Therefore, a de-watering process is required to maintain a moisture content of 9-10%. This process is carried out with de-watering filters and the output product is transported as a concentrate of iron ore to the depot warehouse. The links are also transmitted to the ticker device.

You can contact us to buy and sell this product:

Sales consultant: Ms. Leila Nematzadeh

Ways of communication: Phone number: 02147623014

Phone number: 02147623014

Phone number: 04133660491

Phone number: 04133660491

Phone number: 09120169267

Phone number: 09120169267

WhatsApp Response (Skype): click

WhatsApp Response (Skype): click

Instagram: simurgh_steel_company@

Instagram: simurgh_steel_company@

email: info@simurghsteelco.com

email: info@simurghsteelco.com

email: ironore110@gmail.com

email: ironore110@gmail.com

Facebook: ironore110@

Facebook: ironore110@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

LinkedIn: simurgh-iron-and-steel-company-a68295180@

twitter: CoSimurgh@

twitter: CoSimurgh@